Backflow Preventers: Which Plumbing Device Helps?

Did you know that backflow can contaminate the public drinking supply with fertilizers, pesticides, human waste, chlorine from pools, and soap from sinks and showers? This alarming fact underscores the importance of backflow preventers, which are plumbing devices specifically designed to prevent backflow and protect the purity of drinking water.

Key Takeaways:

- Backflow can introduce harmful substances into the clean water supply.

- Backflow preventers are plumbing devices that ensure water flows in one direction.

- Different types of backflow preventers exist, including air gaps, vacuum breakers, and check valves.

- It is crucial to have a backflow prevention device installed, especially if you have an irrigation system or get water from a well.

- Regular inspection, maintenance, and testing of backflow preventers are essential to ensure their proper functioning.

Understanding Backflow and How it Happens

Backflow is a concerning issue that can lead to the contamination of clean water supplies. It occurs when water flows in the reverse direction, bringing undesirable substances back into the water system. Understanding how backflow happens and its causes is essential for preventing potential risks and ensuring the safety of our drinking water.

The Causes of Backflow

Backflow can be caused by various factors, including changes in water pressure. When there is a break in the main water line or a fire hydrant is opened, the sudden change in pressure can create a backflow situation. This can result in the contamination of the water supply with substances such as fertilizers, pesticides, human waste, chlorine, and soap.

One of the causes of backflow is back pressure, which occurs when the pressure in wastewater systems exceeds that of the fresh water supply. This can happen in pressurized systems like elevated tanks, pumps, or boilers. When the pressure becomes unbalanced, the contaminated water can flow back into the clean water supply, posing a health risk.

Another cause of backflow is back siphonage, which happens when there is negative pressure in the water supply system. This negative pressure can pull water from the sewer line into the clean water line, resulting in the introduction of harmful substances into the water supply.

The Risks of Backflow

Backflow can lead to the contamination of our drinking water with hazardous substances. This poses a serious health risk to consumers, as the ingested contaminants can cause illnesses and other health complications. The presence of fertilizers, pesticides, and chemicals in the water supply can have harmful effects on human health, especially when consumed over an extended period.

Furthermore, backflow can also compromise the quality and taste of drinking water, affecting its usability for cooking, cleaning, and other everyday tasks. It is crucial to address the issue of backflow to protect the health and well-being of individuals and communities.

Understanding the causes and risks of backflow emphasizes the importance of implementing effective prevention measures. In the next section, we will explore the different types of backflow prevention devices that can help safeguard our water supply and mitigate the risks associated with backflow.

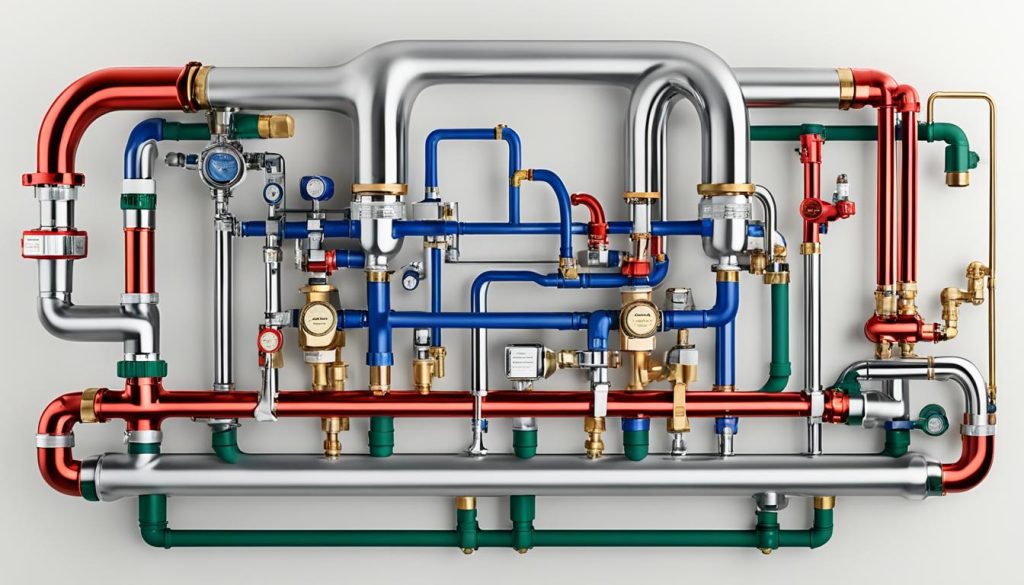

Types of Backflow Prevention Devices

There are different types of backflow prevention devices designed to prevent backflow and protect the purity of drinking water. Some common types include:

- Air Gaps: These are used in sinks and dishwashers to prevent the contamination of drinking water by creating a physical gap between the water outlet and flood level.

- Vacuum Breakers: These are used in hose, faucet, and spigot applications to prevent back siphonage. They contain a check valve that opens an air vent when the system loses pressure, breaking the vacuum and sealing off the water supply line.

- Check Valves: These devices ensure that water flows in one direction by opening and closing based on the pressure on both sides of the valve. They can be installed at the service entrance or at individual water outlets.

It is important to note that all backflow preventers should be tested annually for wear and defects, and businesses are required by law to have them tested.

Do I Need a Backflow Prevention Device?

When it comes to protecting the purity of your water supply, having a backflow prevention device is crucial. Whether you have an irrigation system or get your water from a well, the risk of contamination due to backflow is real. That’s why it is necessary to have a backflow prevention device installed at the water meter.

But even if you don’t have an irrigation system or well, the potential for contamination still exists. Anywhere potable and non-potable water lines connect, there is a possibility of backflow and subsequent contamination of the clean water supply. That’s why it’s recommended to have a backflow preventer installed in these areas as a proactive measure to mitigate the risk.

Homes with older plumbing systems may not have proper backflow prevention devices in place. To ensure the safety of your drinking, cooking, and cleaning water, it’s important to have a licensed plumber inspect your system and install backflow preventers where required.

The consequences of not having a backflow prevention device in place can be severe. Without adequate protection, your water supply is susceptible to potential contamination from various sources, including fertilizers, pesticides, human waste, chlorine, and soap. Don’t compromise the health and safety of your household; prioritize the installation of a backflow preventer to safeguard your potable water.

Installing Backflow Prevention Devices

The installation of backflow prevention devices is crucial to ensuring the purity of your water supply. The specific type and location of the device will determine the installation process. For air gaps, which create a physical separation between the water outlet and flood level, you can easily install them in sinks and dishwashers without the need for a plumber. Simply follow the manufacturer’s instructions to secure the air gap in place.

Vacuum breakers are another type of backflow prevention device that can be easily installed. Just screw them onto the hose, faucet, or spigot and ensure a tight fit. This simple installation step will help prevent back siphonage and protect your water supply from contamination.

When it comes to check valves, the installation process may vary depending on the specific valve type. Some valves can be installed by homeowners themselves, while others may require the expertise of a licensed plumber. To ensure correct installation, it is essential to carefully follow the manufacturer’s guidelines and instructions. Proper installation of check valves will ensure a one-way flow of water and minimize the risk of backflow.

Regular maintenance and testing of backflow prevention devices are crucial to their performance and effectiveness. Be sure to schedule annual inspections and tests to identify any wear or defects in the devices. By prioritizing proper installation, maintenance, and testing, you can ensure that your backflow prevention devices are functioning correctly and safeguarding your water supply from potential contamination.

Source Links

- https://plumbingtoday.biz/blog/what-is-a-backflow-preventer-and-how-does-it-work

- https://en.wikipedia.org/wiki/Backflow_prevention_device

- https://www.freshwatersystems.com/blogs/blog/what-is-a-backflow-prevention-device-and-how-does-it-work

- Investing Wisely: How Windows & Doors in Boost Property Value and Financial Health - April 24, 2025

- The Financial Impact of Personal Injuries: Why Legal Help Matters for Business Owners - April 16, 2025

- The Hidden Financial Costs of Domestic Assault: What Business Owners Need to Know - April 16, 2025