Understanding Polybutylene Pipe Basics

Did you know that polybutylene piping was installed in at least 6 million homes and potentially up to 10 million homes from 1978 to 1995? This form of plastic resin was widely used as a cheaper alternative to traditional copper piping, especially in residential construction in the Sun Belt, Mid Atlantic, and Northwest Pacific states.

Key Takeaways:

- Polybutylene pipe is a form of plastic resin that was extensively used in water supply piping from 1978 to 1995.

- It was seen as a cheaper alternative to traditional copper piping and was widely used in residential construction.

- Polybutylene piping was installed in at least 6 million homes and potentially up to 10 million homes.

- Polybutylene pipes can usually be identified by their gray or white color with a dull finish.

- If issues are detected, repairs or complete replacement of the polybutylene pipes may be necessary.

Identifying Polybutylene Pipe

Polybutylene pipes can be easily identified by their distinct characteristics. Generally, they have a gray or white color with a dull finish, which helps to differentiate them from other types of plumbing pipes.

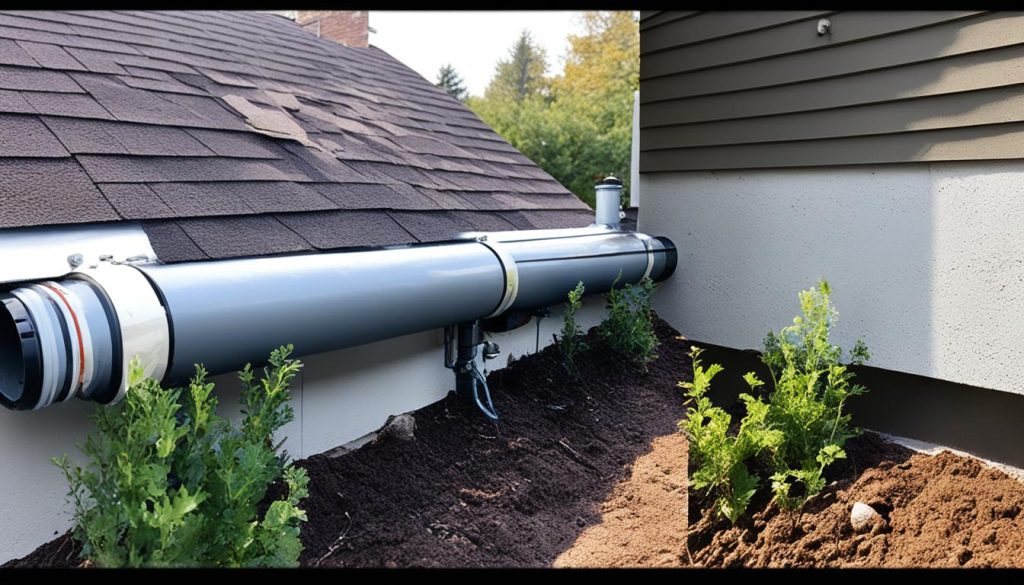

In residential settings, exterior polybutylene pipes that serve as underground mains are typically blue, gray, or black in color. They are commonly found with a diameter of either 1/2″ or 1″, and can enter the home through various entry points such as the basement wall or floor, concrete slab, or crawlspace.

For interior plumbing, polybutylene pipes can often be seen near the water heater, running across unfinished basements, and coming out of walls to supply water to sinks and toilets.

If you suspect that your property may have polybutylene pipes, it is crucial to consult a licensed plumber who specializes in polybutylene pipe inspection. They will thoroughly examine the pipes to confirm their material and assess their condition. This evaluation is essential in understanding the potential hazards associated with polybutylene piping and determining the necessary course of action.

Issues with Polybutylene Pipe

Polybutylene pipes have been associated with several issues. It is believed that oxidants in public water supplies, such as chlorine, can react with the polybutylene piping and fittings, causing them to scale, flake, and become brittle. This can lead to micro-fractures, compromising the structural integrity of the system and potentially causing failures without warning. Other factors, such as improper installation, may also contribute to the failure of polybutylene systems.

If issues are detected, repairs or complete replacement of the polybutylene pipes may be necessary to minimize the risk of damage to the building structure and personal property.

Common Issues with Polybutylene Pipes:

- Brittleness and scaling

- Micro-fractures

- Potential system failures

- Improper installation

When polybutylene pipe plumbing issues arise, it’s important to address them promptly to prevent further damage and potential hazards. Repairing or removing polybutylene pipes requires the assistance of licensed plumbers with expertise in handling such materials.

If you’re unsure whether your plumbing system contains polybutylene pipes or if you’re experiencing any plumbing issues, it’s recommended to consult a professional plumber for a thorough inspection and evaluation. They can provide expert advice on the best course of action for repairing or replacing the polybutylene pipes to ensure the safety and efficiency of your plumbing system.

Polybutylene Pipe Removal and Repair

If your home or building has polybutylene pipes and you’ve experienced plumbing issues, you may need to consider removal or repair options. Depending on the severity of the issues and the overall condition of the pipes, different solutions may be recommended.

Polybutylene pipe repair options may include:

- Spot repairs: Identifying and addressing specific areas of concern, such as corroded fittings or small leaks, while leaving the majority of the pipes intact.

- Partial replacement: Removing and replacing sections of the polybutylene pipes that are damaged or compromised, while leaving the rest of the system intact.

- Complete replacement: Removing and replacing all polybutylene pipes in the building with a more reliable and durable alternative, such as copper or PEX pipes.

Consulting with a licensed plumber is essential to determine the most appropriate course of action for your specific situation. They can assess the condition of the polybutylene pipes, identify any existing or potential issues, and provide recommendations for repair or replacement.

| Issue | Possible Solution |

|---|---|

| Scaling and brittleness | Complete replacement |

| Micro-fractures | Partial replacement or complete replacement |

| Improper installation | Partial replacement or complete replacement |

Removing or repairing polybutylene pipes can help ensure the long-term reliability and safety of your plumbing system. Taking action sooner rather than later can help prevent potential damages and costly repairs in the future.

Polybutylene Pipe Lawsuits and Settlements

During the 1980s, a wave of lawsuits emerged, alleging defects in the manufacturing and installation of polybutylene pipes. These lawsuits resulted in significant financial damages, amounting to hundreds of millions of dollars. Despite never explicitly admitting that polybutylene is defective, the manufacturers agreed to fund a class-action settlement. The settlement began with a minimum initial sum of $950 million.

If you believe you may be eligible for compensation under this settlement, it is crucial to reach out to the appropriate claim company for further information. They will be able to guide you through the process and ensure you have all the necessary documentation to support your claim.

| Name | Settlement Amount | Claim Company |

|---|---|---|

| John Smith | $10,000 | ABC Claims |

| Jane Doe | $5,000 | XYZ Claims |

| Michael Johnson | $7,500 | 123 Claims |

Replacement Options for Polybutylene Pipe

When it comes to dealing with polybutylene pipes, the best option is to replace them entirely. This ensures a long-term solution that minimizes the risk of water damage and mold growth. There are two popular choices for replacing polybutylene pipes: copper piping and PEX (cross-linked polyethylene) pipes.

The Benefits of Copper Piping

Copper piping has been a reliable choice for plumbing for decades. It is durable, resistant to corrosion, and has a long lifespan. Due to its excellent heat and pressure resistance, copper pipes are suitable for both hot and cold water supply. While copper piping may require professional installation, it provides peace of mind and can increase the value of your home.

The Advantages of PEX Pipes

PEX pipes have gained popularity in recent years due to their flexibility, affordability, and ease of installation. PEX pipes are made from a high-density polyethylene material that is resistant to corrosion, freezing, and scale buildup. They are also more resistant to bursting than traditional copper pipes, making them a reliable choice for replacing polybutylene pipes. PEX pipes can be easily connected using crimping or push-fit systems, saving time and reducing installation costs.

To demonstrate the differences between copper piping and PEX pipes, here is a comparison table:

| Copper Piping | PEX Pipes | |

|---|---|---|

| Material | Copper | Polyethylene |

| Durability | High | High |

| Resistance to Corrosion | Excellent | Excellent |

| Flexibility | Low | High |

| Installation Cost | Higher | Lower |

| Installation Difficulty | Requires professional installation | DIY-friendly |

| Lifespan | 50+ years | 50+ years |

Before replacing your polybutylene pipes, it’s important to note that most home insurance policies either exclude coverage for homes with polybutylene pipes or charge higher premiums. Replacing the pipes can not only provide greater peace of mind but also help maintain the value of your property.

If replacing the pipes is not immediately feasible, temporary repairs can be made by cutting out the affected sections and replacing them with PEX pipes. However, it is recommended to consult a licensed plumber to assess the condition of your pipes and determine the best course of action.

Kitec Piping and its Issues

Kitec piping, also known as polybutylene, was introduced as a cost-effective alternative to copper pipes from 1995 to 2007. However, homeowners have experienced significant issues with these pipes, including spontaneous bursting, leading to water damage and mold growth. One of the main causes of these failures is the breakdown of the fittings used in Kitec piping due to high zinc content.

To prevent leaks and potential damage, replacing all water pipes in a home that contain Kitec piping is highly recommended. It’s crucial to take action promptly to mitigate the risk of bursting pipes and the resulting water damage. Additionally, it’s important to note that homeowners’ insurance policies may not cover homes with Kitec piping, or they may charge higher premiums due to the known plumbing issues associated with these pipes.

If you suspect that your home may have Kitec piping, it’s advisable to consult a licensed plumber to inspect the pipes and assess their overall condition. They can provide you with the necessary guidance and assistance to replace the Kitec piping with a more reliable and durable plumbing system, ensuring the long-term integrity of your home’s water supply.

Source Links

- https://www.polybutylene.com/poly.html

- https://mtcopeland.com/blog/what-are-polybutylene-pipes-and-why-are-they-a-problem/

- https://widespreadinspect.com/what-is-polybutylene-piping/

- Investing Wisely: How Windows & Doors in Boost Property Value and Financial Health - April 24, 2025

- The Financial Impact of Personal Injuries: Why Legal Help Matters for Business Owners - April 16, 2025

- The Hidden Financial Costs of Domestic Assault: What Business Owners Need to Know - April 16, 2025