Connecting Copper Pipe to PVC – Easy Guide

Did you know that in the plumbing industry, copper pipe and PVC (polyvinyl chloride) are two of the most commonly used materials for pipe installations? While copper pipe is known for its durability and corrosion resistance, PVC is popular for its affordability and versatility.

But what happens when you need to connect these two different types of pipes? The good news is that it can be done easily with the right tools and techniques. In this article, I will guide you step-by-step on how to connect copper pipe to PVC for your DIY plumbing projects.

Key Takeaways:

- Connecting copper pipe to PVC requires the use of transition fittings or adapters.

- There are multiple methods available, including compression fittings, push-fit fittings, soldering, and glue.

- Choose the method that best suits your specific plumbing needs.

- Always ensure the connection is secure and watertight to avoid leaks.

- Consider the compatibility and corrosion resistance of the materials before connecting copper pipe to PVC.

Tools and Materials for Connecting Copper Pipe to PVC

Before starting the connection process to transition from copper pipe to PVC, it’s important to gather the necessary tools and materials. Having the right equipment ensures a smooth and successful plumbing project. Here are the essential tools and materials you’ll need:

- Pipe wrench: A pipe wrench enables you to tighten and loosen pipes securely. It provides a strong grip, making it easier to work with copper and PVC pipes.

- Screwdriver: A versatile 4-in-1 screwdriver is the go-to tool for various tasks, including loosening or tightening screws and removing pipe fittings.

- Pliers: Slip-joint pliers are useful for holding pipes while performing connections or repairs. They provide a secure grip and can be adjusted to fit different pipe sizes.

- Plumber tape: Also known as Teflon tape, plumber tape is used to create a tight seal between threaded connections. It prevents leaks and ensures a watertight joint.

- Wire brush: A wire brush is essential for cleaning and preparing the surface of copper pipes, eliminating any debris or oxidation that may hinder proper adhesion.

- Soldering iron: If you’re using soldered connections, a soldering iron is necessary to heat the solder and join the copper pipe to the fitting.

- Flux paste: Flux paste is applied to the copper pipe before soldering to ensure a smooth flow of solder and a secure bond between the pipe and fitting.

Having these tools ready will make the process of connecting copper pipe to PVC easier and more efficient.

Methods for Connecting Copper Pipe to PVC

When it comes to connecting copper pipe to PVC, there are several methods you can choose from, depending on your project requirements. Each method offers its own benefits and considerations. Here are the most commonly used methods:

1. Compression Fittings

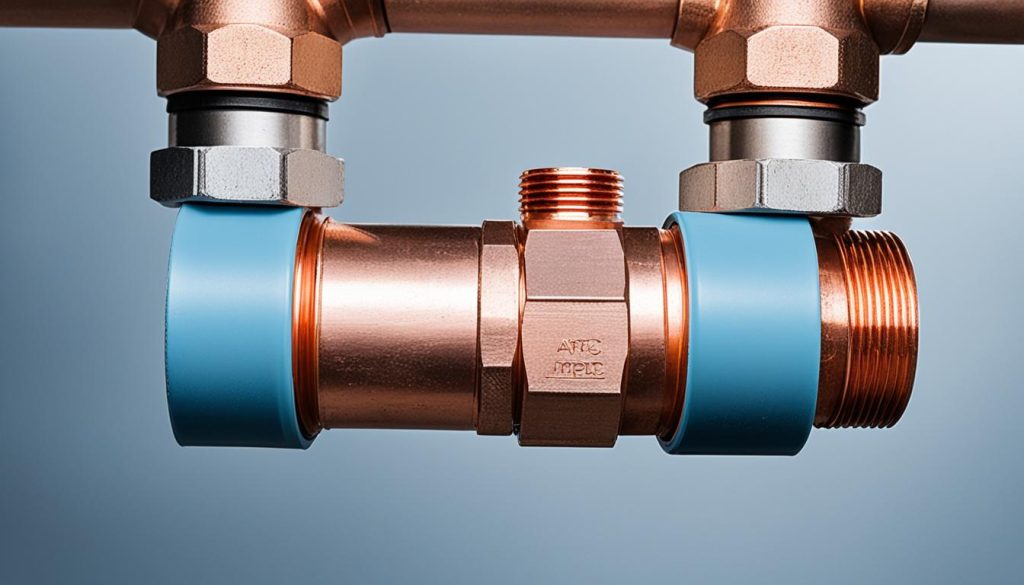

Compression fittings provide a secure and reliable connection between copper pipe and PVC. They consist of three main components: a compression nut, a compression ring, and a brass ferrule. To create a connection, you’ll need to clean the pipes, insert the brass ferrule onto the copper pipe, and then tighten the compression nut to compress the ring and create a watertight seal.

2. Push-Fit Fittings

Push-fit fittings offer a quick and hassle-free way to connect copper pipe to PVC. These fittings have a built-in rubber O-ring or gasket that creates a watertight seal without the need for glue or soldering. Simply insert the pipe into the fitting until it reaches the stop, and you’re done. Push-fit fittings are ideal for shorter pipe connections and are easily removable if needed.

3. Soldering

Soldering is a traditional method used to join copper pipe to PVC. It involves heating the copper pipe and applying solder to create a strong bond. This method requires soldering skills and the use of a soldering iron and flux paste. It’s important to clean the pipes thoroughly, apply flux to the copper pipe, and carefully heat the joint while applying solder to ensure a secure connection.

4. Glue

Gluing is another option for connecting copper pipe to PVC. It is commonly used in PVC plumbing systems. To connect the two pipes with glue, you’ll need a male-threaded fitting and a female-threaded fitting. Apply PVC glue to both fittings and insert the copper and PVC pipes respectively. Hold them together firmly until the glue dries completely, creating a strong bond.

5. Other Options

In addition to the above methods, there are a few other options available for connecting copper pipe to PVC. Rubber couplers or hose clamps can be used as temporary fixes or for joining pipes of different diameters. Putty glue can also be used to bond copper and PVC surfaces together, providing an alternative adhesive option.

When selecting a method for connecting copper pipe to PVC, consider factors such as the complexity of the project, the required strength and durability of the connection, and the available tools and materials. Each method has its own advantages and limitations, so choose the one that best suits your specific needs.

| Connection Method | Advantages | Considerations |

|---|---|---|

| Compression Fittings | Secure and long-lasting connection | Requires cleaning and tightening |

| Push-Fit Fittings | Easy and quick installation | More suitable for shorter connections |

| Soldering | Strong and reliable bond | Requires soldering skills and tools |

| Glue | Convenient for PVC plumbing systems | Proper surface preparation is crucial |

| Other Options | Temporary fixes or alternative adhesives | May not provide long-term durability |

Connecting Copper Pipe to PVC with Compression Fittings

If you’re looking for a secure and reliable method to connect copper pipe to PVC, compression fittings are a great option. This method ensures a watertight seal between the two types of pipes, making it ideal for various plumbing projects. Follow these steps to connect copper pipe to PVC using compression fittings:

- Clean the copper pipe: Before starting the connection process, clean the copper pipe thoroughly to remove any dirt or debris. This will ensure a clean surface for the compression fitting to seal properly.

- Prepare the PVC pipe: Similarly, clean the PVC pipe to remove any dirt or particles that may interfere with the connection.

- Apply flux paste: Apply flux paste to the cleaned copper pipe. Flux is a chemical compound that helps facilitate the soldering process by preventing oxidation and ensuring a secure bond.

- Insert the compression fitting: Insert the compression fitting into the prepared copper pipe. The compression fitting consists of a compression nut, a compression ring, and a compression sleeve.

- Tighten the nut: Use a wrench or pliers to tighten the compression nut onto the fitting. Ensure that it is tightened securely to create a watertight seal between the copper pipe and the compression fitting.

It is crucial to check for corrosion resistance before connecting the copper pipe to PVC. Plastic pipes, such as PVC, are more sensitive to sunlight and potential corrosion, so ensure that the connection is protected or shielded from direct sunlight. This will help maintain the integrity and durability of your plumbing system.

Remember, compression fittings provide a reliable and durable connection between copper pipe and PVC. They are commonly used in DIY plumbing projects and are known for their corrosion resistance and long-lasting performance.

| Pros of Using Compression Fittings | Cons of Using Compression Fittings |

|---|---|

| Secure and watertight connection | Requires additional tools for installation |

| Corrosion-resistant | May be more expensive than other connection methods |

| Durable and long-lasting | May require more time for installation compared to push-fit fittings |

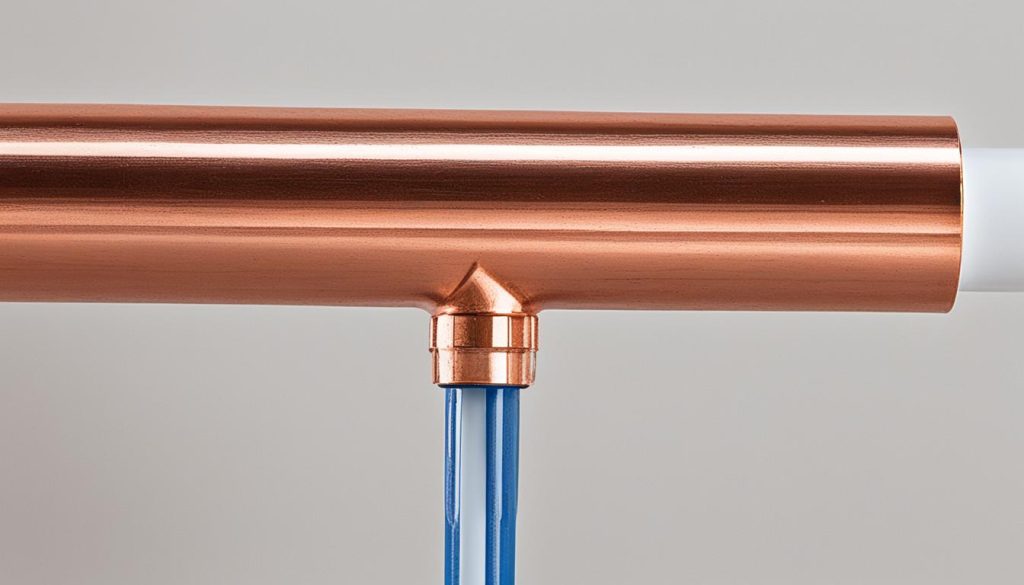

Connecting Copper Pipe to PVC with Push-Fit Fittings

When it comes to connecting copper pipe to PVC, push-fit fittings are a convenient and hassle-free option. With push-fit fittings, you can easily join copper and PVC pipes without the need for glue or complicated installation processes. These fittings provide a secure and watertight seal, making them ideal for various plumbing projects.

To connect copper pipe to PVC using push-fit fittings, follow these simple steps:

- Cut the copper pipe and PVC pipe to the desired length using a pipe cutter.

- Remove any rough edges or burrs from the cut ends of both pipes using a deburring tool or sandpaper.

- Slide a push-fit fitting onto one end of the copper pipe.

- Insert the other end of the push-fit fitting into the PVC pipe.

- Push the fitting and pipe together until they create a secure and watertight seal.

Push-fit fittings make it easy to connect copper pipe to PVC because they have built-in seals that ensure a leak-free connection. This eliminates the need for glue, which can be messy and time-consuming to apply properly. Push-fit fittings are especially suitable for shorter pipe connections and are commonly used in residential and commercial plumbing applications.

For a visual representation of how to connect copper pipe to PVC using push-fit fittings, refer to the image below:

| Advantages of Using Push-Fit Fittings to Connect Copper Pipe to PVC | Disadvantages of Using Push-Fit Fittings to Connect Copper Pipe to PVC |

|---|---|

|

|

Connecting Copper Pipe to PVC with Soldering or Glue

When it comes to connecting copper pipe to PVC, there are two common methods you can choose from: soldering and glue. Let’s take a closer look at how each method works and the steps involved.

Soldering Copper Pipe to PVC

Soldering is a popular method for connecting copper pipe to PVC when a watertight seal is required. It involves using heat to melt solder and fuse the pipes together. Here’s a step-by-step guide:

- Clean both the copper pipe and the PVC pipe thoroughly using a wire brush to remove any debris or corrosion.

- Apply flux paste to the end of the copper male-adapter fitting. Flux helps create a clean surface for soldering.

- Insert the copper male-adapter fitting into the copper pipe.

- Heat the joint using a soldering iron until the solder melts and bonds the copper pipe and the male-adapter fitting together.

- Allow the joint to cool and inspect for any leaks.

It is important to note that soldering should be done carefully and with proper safety precautions, as it involves working with high heat.

Gluing Copper Pipe to PVC

If soldering is not desirable or suitable for your project, gluing can be an alternative method for connecting copper pipe to PVC. Here’s how you can do it:

- Choose a male-threaded fitting for the copper pipe and a female-threaded fitting for the PVC pipe.

- Clean both the copper pipe and the PVC pipe to ensure a clean and smooth surface.

- Apply PVC glue to the male-threaded fitting and the female-threaded fitting.

- Insert the copper pipe into the male-threaded fitting and the PVC pipe into the female-threaded fitting.

- Hold the pipes together firmly until the glue sets and creates a secure bond.

Gluing provides a more convenient and flexible option for connecting copper pipe to PVC, as it does not require the use of heat or soldering equipment.

Corrosion Resistance and Considerations

Before connecting copper pipe to PVC, it is important to consider the compatibility of the materials and their resistance to corrosion. While copper pipe is known for its corrosion resistance, PVC is more sensitive to sunlight and can degrade over time when exposed to certain chemicals.

It is recommended to check for corrosion resistance and choose the appropriate method and materials to ensure a reliable and long-lasting connection for your plumbing system.

Pros and Cons of Soldering and Gluing

| Soldering | Gluing | |

|---|---|---|

| Pros |

|

|

| Cons |

|

|

Adapters for Connecting Copper Pipe to PVC

When it comes to connecting copper pipe to PVC, having the right adapters is essential. There are several options available, each with its own unique features and benefits. Whether you need transition fittings, PVC to copper adapters, a 1 1/2 copper to PVC adapter, slip connections, solvent welds, thread adapters, or shark bite fittings, there is an adapter that can provide a secure and reliable connection between the two types of pipes.

Transition fittings are designed specifically for joining copper and PVC pipes, making them a popular choice for plumbing projects. PVC to copper adapters are another great option, allowing you to easily connect PVC pipes to copper pipes. If you are working with a 1 1/2 inch copper pipe and need to connect it to PVC, a 1 1/2 copper to PVC adapter will do the job.

For those who prefer a simpler installation process, slip connections and solvent welds offer convenience and ease of use. Slip connections allow for easy joining and disconnection, while solvent welds create a strong bond between the copper and PVC pipes. Thread adapters are ideal for situations where you need to connect threaded copper pipe to PVC. And if you want a quick and hassle-free connection, shark bite fittings provide a simple push-to-connect solution.

When choosing the right adapter for your project, consider factors such as pipe size, compatibility, and the specific requirements of your plumbing system. With the right adapter, you can achieve a secure and reliable connection between your copper pipe and PVC, ensuring your plumbing projects are successful.

Source Links

- https://www.plumbersderby.org.uk/how-to-connect-pvc-to-copper-plumbing/

- https://pipesyard.com/how-to-connect-pvc-to-copper-pipe/

- https://www.pipsisland.com/how-to-connect-pvc-to-copper-pipe/

- Investing Wisely: How Windows & Doors in Boost Property Value and Financial Health - April 24, 2025

- The Financial Impact of Personal Injuries: Why Legal Help Matters for Business Owners - April 16, 2025

- The Hidden Financial Costs of Domestic Assault: What Business Owners Need to Know - April 16, 2025