Understanding Standpipes: Your Fire Safety Ally

Did you know that standpipes play a crucial role in containing and extinguishing fires in various types of buildings? These systems are not only vital for protecting the structure, but also for safeguarding the lives of occupants. Whether it’s a high-rise, shopping mall, or warehouse, standpipes serve as a reliable source of water, enabling firefighters and building occupants to combat fires effectively.

Key Takeaways:

- A standpipe system is an arrangement of piping, valves, hose connections, and allied equipment installed in a building or structure for fire protection.

- There are four types of standpipe systems: wet, automatic dry, semi-automatic dry, and manual dry.

- Standpipes are classified into three classes: Class 1 for firefighting personnel, Class 2 for building occupants, and Class 3 combining firefighting and occupant hose capabilities.

- Standpipe systems consist of various components, including piping, valves, and hose connections.

- Maintenance and adherence to regulations are essential for the effective operation of standpipe systems.

Types of Standpipe Systems

Standpipe systems serve as a crucial component of fire protection in buildings, providing a reliable water supply for firefighting purposes. These systems can be classified into four main types: wet, automatic dry, semi-automatic dry, and manual dry. Each type has its own unique characteristics and requirements.

1. Wet Systems

A wet standpipe system is the most common type and is widely used in buildings. It is characterized by having water constantly present in the pipes, supplied by a reliable water source such as a municipal water supply or a dedicated water tank. This ensures immediate access to water when needed, allowing for a quick response to fire emergencies. Wet systems are particularly suitable for buildings where water pressure can be maintained consistently.

2. Automatic Dry Systems

Automatic dry standpipe systems are designed to prevent freezing in areas where temperatures can drop below freezing point. These systems store pressurized air in the standpipe, keeping the water from entering the pipes until a hose valve is opened. When the valve is opened, the pressure is released, allowing the water to flow and extinguish the fire. Automatic dry systems are commonly used in buildings where the pipes are exposed to cold temperatures or subject to freezing conditions.

3. Semi-Automatic Dry Systems

Semi-automatic dry standpipe systems utilize a combination of air and water to provide fire protection. The pipes can be either pressurized or non-pressurized, depending on the design. Water enters the system when an actuation device, such as a fire alarm or sprinkler system, is activated. Semi-automatic dry systems are versatile and can be adapted to various building types and fire protection needs.

4. Manual Dry Systems

Manual dry standpipe systems do not have water or air in the pipes as a standard feature. Instead, they rely on fire department apparatus to supply water through the standpipe during firefighting operations. These systems are typically used in buildings where the water supply may be limited or unreliable but can still provide an essential means of fire suppression when necessary.

In order to ensure the effectiveness and reliability of standpipe systems, regular maintenance is essential. Standpipe components should be inspected, tested, and maintained according to the manufacturer’s guidelines and local regulations. This includes checking for any leaks, corrosion, or obstructions in the pipes, as well as ensuring that valves, hose connections, and other allied equipment are in proper working order. Proper maintenance and adherence to standpipe requirements not only enhance the safety of building occupants but also provide firefighters with the essential tools they need to combat fires effectively.

Classifications of Standpipes

Standpipes in buildings are classified into three categories: Class 1, Class 2, and Class 3. Each classification serves a specific purpose and is designed to meet the needs of different users in emergency situations.

Class 1 Standpipe

A Class 1 standpipe is specifically designed for firefighting personnel. It features a two-and-a-half-inch outlet, which allows for the efficient delivery of water during firefighting operations. The outlets on Class 1 standpipes may vary in design and can include pressure-reducing devices that help control the flow of water.

Class 2 Standpipe

A Class 2 standpipe is intended for use by building occupants. It is equipped with a reduced standpipe outlet and a 100-foot hose line of one-and-a-half-inch hose. While Class 2 standpipes can also be used by firefighters, their primary function is to provide building occupants with a means to respond to an emergency before the arrival of the fire department.

Class 3 Standpipe

Class 3 standpipes combine features of both Class 1 and Class 2 standpipes. They are designed with an exposed two-and-a-half-inch outlet for firefighting personnel and also provide an occupant hose option. This hybrid classification offers flexibility and ensures that both firefighters and building occupants can effectively utilize the standpipe system in emergency situations.

Understanding the classifications of standpipes is crucial in determining their appropriate use and ensuring that adequate fire protection measures are in place. Whether it’s the dedicated outlet of a Class 1 standpipe, the occupant-focused functionality of a Class 2 standpipe, or the versatility of a Class 3 standpipe, each classification plays a vital role in safeguarding buildings and the people within them.

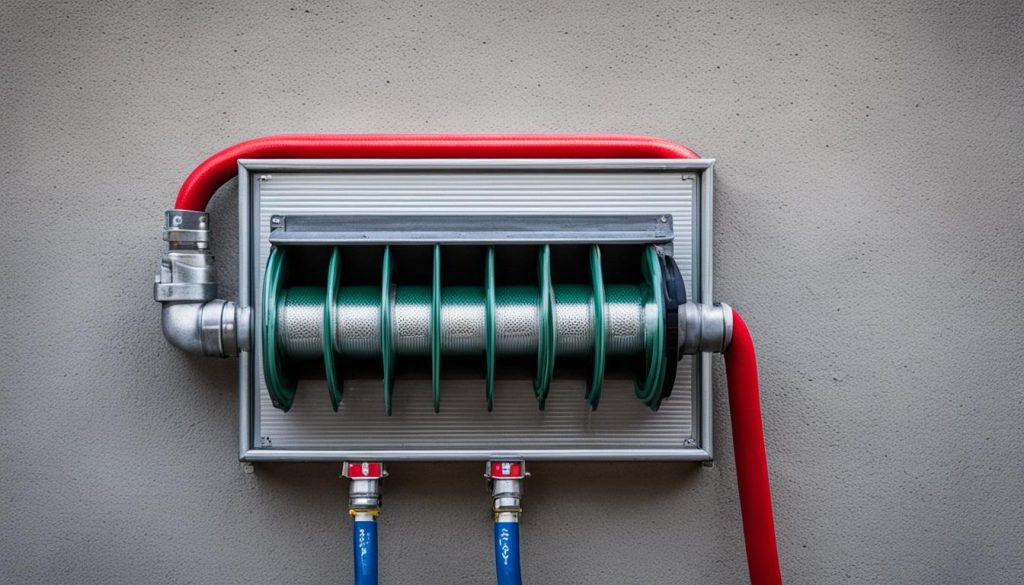

Functions and Components of Standpipe Systems

Standpipe systems play a crucial role in ensuring effective firefighting by providing a reliable method of delivering water within a structure. By efficiently transporting water from one area to another, standpipes enable firefighters to quickly and efficiently extinguish fires. These systems consist of various components that work together to facilitate the flow of water and support firefighting operations.

Components of a Standpipe System

A standpipe system comprises several key components, each serving a specific function:

- Piping: The pipes form the backbone of the standpipe system, carrying water from a water source to the designated areas within the building. They are typically made of durable materials such as steel or ductile iron to withstand the rigors of firefighting operations.

- Valves: Valves regulate the flow of water within the standpipe system. They allow firefighters to open and close specific sections of the system, controlling the distribution of water to where it is needed most.

- Hose Connections: Hose connections are the access points where firefighters can connect hoses to the system. These connections are strategically placed throughout the building, ensuring that firefighters have easy access to water when combating a fire.

- Allied Equipment: Allied equipment includes various devices and accessories that enhance the functionality and safety of the standpipe system. This can include items such as pressure gauges, pressure-reducing devices, and fire department connections (FDCs).

Proper installation of a standpipe system requires careful planning and adherence to local regulations and building codes. Installers must consider factors such as available water supply, pipe sizing, and the placement of components to ensure optimal performance in case of a fire emergency.

Standpipe Fire Hose Stations

Standpipe fire hose stations play a crucial role in providing immediate fire protection during those critical first minutes of a fire incident. These stations are equipped with piping, valves, hose connections, and allied equipment installed in a building or structure. They serve as a first line of defense, allowing building occupants to manually apply water to fires before the arrival of the fire department.

Standpipe fire hose stations are designed to be easily accessible, strategically located throughout the building to ensure swift response in case of an emergency. They provide a reliable means for occupants to effectively respond to a fire and minimize the potential damage.

Standpipe Fire Hose Station Components

A typical standpipe fire hose station comprises the following components:

- Piping: The piping system connects the standpipe to the water supply and facilitates the flow of water to the hose connections.

- Valves: Valves are used to control the flow of water within the standpipe system.

- Hose Connections: Hose connections are where the fire hoses are attached to the standpipe system. They allow for the manual application of water during a fire incident.

- Allied Equipment: Allied equipment such as pressure gauges, pressure-reducing devices, and nozzle attachments may be present in standpipe fire hose stations to enhance functionality and adaptability.

These components work together to ensure the standpipe fire hose stations are ready for immediate use in the event of a fire emergency.

| Advantages of Standpipe Fire Hose Stations | Disadvantages of Standpipe Fire Hose Stations |

|---|---|

|

|

While standpipe fire hose stations provide immediate fire protection and empower building occupants to take action, it is vital to understand their limitations. Occupants should receive proper training on the proper use of the equipment and understand when it is safe to intervene. Standpipe fire hose stations are most effective when used in the early stages of a fire incident and in conjunction with professional firefighting efforts.

Importance of Standpipe Maintenance

Proper maintenance of standpipe systems is crucial to ensure their functionality in times of emergency. Regular inspections, testing, and maintenance should be conducted to identify and address any potential issues or malfunctions. These routine maintenance activities play a vital role in the overall effectiveness and reliability of standpipe systems.

Standpipe maintenance involves various tasks that are essential for the optimal performance of the system. These tasks can include:

- Inspecting standpipe components such as valves, hoses, and fittings for signs of wear or damage.

- Testing the water supply to ensure an adequate flow and pressure.

- Checking the functionality of standpipe valves and fire department connections.

- Verifying the accessibility and proper labeling of standpipe equipment.

Regular maintenance not only helps identify potential issues but also ensures compliance with standpipe requirements set by local regulations and authorities. By adhering to these requirements, building owners can contribute to the safety of their occupants and minimize the risk of fire-related hazards.

Benefits of Standpipe Maintenance

Effective standpipe maintenance offers several benefits:

- Improved Reliability: Regular maintenance helps identify and address any malfunctions or deficiencies in the system, ensuring that it functions as intended during emergencies.

- Extended Lifespan: By promptly addressing minor issues through maintenance, the overall lifespan of the standpipe system can be extended, saving costs on premature replacements.

- Compliance with Regulations: Regular maintenance helps ensure that standpipe systems meet the necessary regulatory requirements, avoiding potential penalties or legal consequences.

- Enhanced Occupant Safety: Well-maintained standpipe systems provide a reliable means of fire protection, enhancing the safety of building occupants and facilitating effective evacuation.

Investing in proper standpipe maintenance is a proactive approach to safeguarding lives and property. By prioritizing regular inspections, testing, and maintenance, building owners can ensure that their standpipe systems are ready to respond effectively in the event of a fire emergency.

| Standpipe Maintenance Checklist |

|---|

| Regular inspections of standpipe components |

| Testing the water supply for adequate flow and pressure |

| Checking the functionality of standpipe valves and fire department connections |

| Ensuring proper accessibility and labeling of standpipe equipment |

Standpipe and Sprinkler Systems

In many buildings, standpipe systems and sprinkler systems are installed together to provide comprehensive fire protection. Both systems work in tandem to ensure the safety of occupants and minimize property damage in the event of a fire. Fire department connections (FDCs) serve as the primary water supply for both the standpipe and sprinkler systems, allowing firefighters to connect their apparatus and deliver water quickly and efficiently.

When standpipe and sprinkler systems are installed together, it is important to clearly label the FDCs to indicate which system they are intended for. This helps firefighters easily identify and connect the right equipment during an emergency. In some cases, separate FDCs are provided for each system, ensuring dedicated water supply for both. Alternatively, a blended FDC can be used, which is designed to supply water to both the standpipe and sprinkler systems.

The integration of standpipe and sprinkler systems provides a comprehensive firefighting solution. While the standpipe system allows firefighters and building occupants to manually apply water through hose connections, the sprinkler system works automatically, activating when heat is detected and releasing water to suppress and control the fire. Together, these systems offer a multi-layered approach to fire safety, ensuring rapid response and effective fire suppression.

Benefits of Integrating Standpipe and Sprinkler Systems

Integrating standpipe and sprinkler systems offers several benefits:

- Enhanced firefighting capabilities: With both systems in place, firefighters have multiple options to deliver water, depending on the location and intensity of the fire. This flexibility allows for more effective fire suppression.

- Improved occupant safety: Standpipe systems provide building occupants with the means to fight small fires and evacuate safely before the arrival of firefighters. Sprinkler systems, on the other hand, automatically activate to control the spread of the fire, giving occupants additional time to escape.

- Minimized property damage: The combination of standpipe and sprinkler systems helps to contain and extinguish fires quickly, minimizing property damage and reducing the overall impact of a fire incident.

- Compliance with regulations: Many building codes and regulations require the installation of both standpipe and sprinkler systems in certain types of buildings, such as high-rises and commercial properties. Integrating these systems ensures compliance with safety standards.

Comparison of Standpipe and Sprinkler Systems

| Standpipe System | Sprinkler System |

|---|---|

| Requires manual activation | Activates automatically when heat is detected |

| Used primarily by firefighters and building occupants | Primarily designed for automatic fire suppression |

| Water is delivered through hose connections | Water is released from sprinkler heads |

Combining standpipe and sprinkler systems provides the best of both worlds, empowering building occupants to take immediate action during a fire emergency while ensuring automatic fire protection and suppression. By integrating these systems and adhering to maintenance and testing protocols, buildings can enhance their fire safety measures and protect occupants and property.

Standpipe System and Fire Department Connection

The fire department connection (FDC) plays a crucial role in the installation of a standpipe system, allowing for the supply of water and enabling the fire department to connect their apparatus quickly and efficiently. It is essential to ensure that the FDC is kept free of debris and properly labeled to avoid confusion with sprinkler systems.

When supplying water to the standpipe system, it is recommended to do so gradually or increase the pressure slowly to prevent any potential pipe or valve malfunctions. This cautious approach helps maintain the integrity of the system and ensures smooth operation when it is most needed.

Standpipe system installations should always adhere to local regulations and requirements to ensure proper functionality and accessibility for the fire department. By following these guidelines and working closely with fire safety experts, you can create a reliable standpipe system that will provide effective fire protection to your building or structure.

Source Links

- https://ohsonline.com/Articles/2006/08/Standpipe-Fire-Hose-Stations-Save-Lives-Protect-Property.aspx

- https://www.firefightingincanada.com/dec2012-13831/

- https://www.surrey.ca/sites/default/files/media/documents/CWCConstructionFireSafetyManual.pdf

- Investing Wisely: How Windows & Doors in Boost Property Value and Financial Health - April 24, 2025

- The Financial Impact of Personal Injuries: Why Legal Help Matters for Business Owners - April 16, 2025

- The Hidden Financial Costs of Domestic Assault: What Business Owners Need to Know - April 16, 2025