Understanding Plumbing Risers: Their Role & Function

Did you know that plumbing risers, also known as riser mains, play a crucial role in multi-story buildings by allowing water to move against gravity? These vertical pipes carry fresh water from lower floors to upper floors, ensuring a reliable water supply throughout the building.

Key Takeaways:

- Risers are vertical pipes that carry fresh water from lower floors to upper floors in multi-story buildings.

- They are essential in maintaining a reliable water supply throughout the building.

- Risers can be made from various materials, including plastic, copper, brass, and galvanized steel.

- The lifespan of risers depends on the material used, but regular inspections and maintenance are essential.

- Signs that indicate the need for riser replacement include water pressure decline, discoloration of water, leaks, and high water bills.

What are Risers in Plumbing?

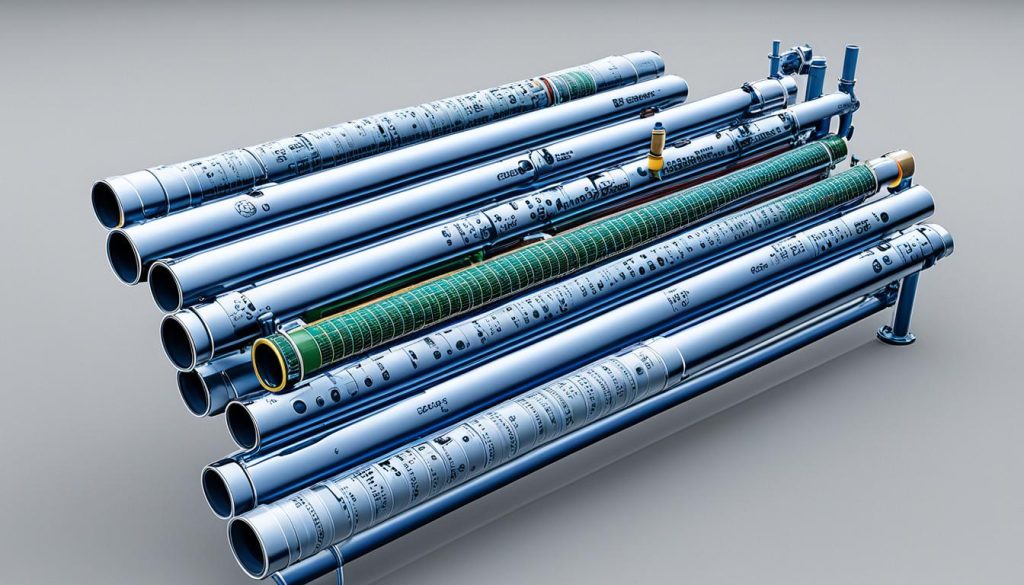

Risers in plumbing refer to the vertical pipes that carry fresh water from lower floors to upper floors in a building. They are also known as riser mains and are an essential part of multi-story buildings. Risers allow water to move against gravity and have features such as backflow preventers to ensure the correct flow of water through the system.

Plumbing risers are made from various materials, including plastic, copper, brass, and galvanized steel. The choice of material depends on the building’s age and the specific requirements of the plumbing system. Plastic risers are commonly used due to their durability, corrosion resistance, and affordability. Copper and brass risers are preferred in older buildings for their longevity and resistance to high temperatures. Galvanized steel risers are suitable for industrial and commercial applications due to their strength and resistance to corrosion.

Over time, risers in plumbing may need to be replaced due to factors such as age, use, maintenance history, and the presence of corrosive chemicals in the water. Signs that indicate the need for riser replacement include a gradual decline in water pressure, discoloration of the water, signs of leaks on walls, and high water bills.

Regular inspections and maintenance are important for identifying the need for riser replacement and ensuring the efficient functioning of the plumbing system. Proper installation and maintenance of risers are crucial for the reliable distribution of fresh water throughout the building and the prevention of water damage.

Comparison of Riser Materials

| Material | Lifespan | Advantages | Disadvantages |

|---|---|---|---|

| Plastic | Approximately 40 years | Durable, corrosion-resistant, affordable | May become brittle over time, limited temperature resistance |

| Copper | Approximately 70 years | Longevity, resistance to high temperatures | Expensive, may corrode in certain water conditions |

| Brass | Approximately 70 years | Longevity, resistance to high temperatures, low lead content | Expensive, limited availability |

| Galvanized Steel | Approximately 50 years | Strength, corrosion resistance | Can be difficult to install, may corrode over time |

Signs You Need Riser Replacement

In any building, there are telltale signs that indicate the need for riser replacement. By recognizing these signs, you can take action to ensure the efficient functioning of your plumbing system. Here are some key indicators that it may be time to replace your risers:

- Gradual Water Pressure Decline: If you notice a gradual decrease in water pressure, especially on upper floors, it could be a sign of decaying or blocked risers. This can impact the overall water flow and affect the functionality of your plumbing system.

- Discoloration of Water: Rust-colored or yellow water is a common sign of deteriorating metal risers. Over time, corrosion can occur, leading to discoloration and potentially compromising the quality of the water flowing through your pipes.

- Signs of Leaks on Walls: Water staining or dampness on walls can indicate a leaking riser behind the surface. If left unaddressed, this can lead to further damage to your walls and potential water damage to your property.

- High Water Bills: A sudden increase in your water bills without any significant changes in water usage can be a warning sign of leaking risers. Leaks within the risers can result in water wastage and unnecessary expenses.

Regular inspections of your plumbing system, including the risers, are crucial for identifying these signs and determining the need for replacement. By addressing these issues promptly, you can prevent further damage and ensure the long-term functionality of your plumbing system.

The function of risers in plumbing is integral to the effective distribution of fresh water throughout a building. They play a vital role in maintaining water pressure and delivering water to individual outlets on each floor. Without properly functioning risers, water flow can be disrupted, causing inconvenience and potential damage.

It is essential to recognize the importance of risers in plumbing and prioritize their maintenance and replacement when necessary. By doing so, you can ensure the smooth operation of your plumbing system and avoid costly repairs in the future.

Types of Risers in Plumbing

In plumbing, different types of risers are used to serve specific purposes in the water distribution system. Understanding the various types of risers can help in designing and planning an efficient plumbing system. Let’s explore the main types of risers commonly used in plumbing:

Main Risers

Main risers, also known as primary risers, are the primary vertical pipes that carry water from the main supply line to various floors of a building. These risers play a crucial role in the distribution of water throughout the building, ensuring a sufficient supply of fresh water to each floor. Main risers are usually larger in diameter and located in the core or service areas of the building. They are designed to handle the high water flow rates required for multi-story buildings.

Branch Risers

Branch risers are secondary vertical pipes that branch off from the main riser to deliver water to specific areas or outlets. These risers serve as distribution lines, supplying water to different sections of a floor or specific fixtures within a room. Branch risers are generally smaller in diameter compared to main risers and are often hidden within walls or other concealed spaces. They ensure the efficient delivery of water to specific areas, reducing water wastage and maintaining water pressure.

Individual Risers

Individual risers are small-diameter pipes that connect individual outlets, such as faucets or toilets, to a branch riser. These risers regulate the flow of water to each outlet, allowing for precise control and distribution. They play a crucial role in isolating individual outlets for maintenance or repair without affecting the entire plumbing system. Individual risers ensure the effective operation of each fixture and facilitate the prompt resolution of any issues that may arise.

Choosing the appropriate type of riser depends on various factors, such as the type of fluid being transported, pressure requirements, and the building’s design. Each type of riser has a specific function in the plumbing system, contributing to the overall efficiency and functionality of the water distribution system.

Installation of Risers in Plumbing

The installation of risers in plumbing is a multi-step process that requires careful planning and execution. By following the correct installation procedures, you can ensure the efficient and reliable distribution of water throughout the building. Here are the key steps involved in installing risers:

- Step 1: Selecting the Right Riser: The first step in the installation process is selecting the appropriate type and size of riser. Consider factors such as the type of fluid being transported, pressure requirements, and the building’s design. This ensures that the riser can effectively meet the specific needs of your plumbing system.

- Step 2: Preparing the Installation Site: Before installing the riser, it’s important to prepare the installation site. This involves clearing the area of any obstructions and making any necessary modifications to the building’s structure. By ensuring a clean and suitable installation site, you can facilitate a smooth installation process.

- Step 3: Attaching the Riser: Once the installation site is prepared, the riser is securely attached to the structure. This ensures that the riser remains stable and in the correct position. Secure attachment methods, such as brackets or clamps, are used to keep the riser in place.

- Step 4: Making Connections: Connections are then made to the main supply line and individual outlets. These connections allow water to flow into the riser and be distributed to various floors and outlets within the building. The connections must be made using precise measurements and cutting techniques to ensure a proper fit.

Proper installation of risers in a plumbing system is crucial for maintaining the integrity of the system and ensuring the efficient flow of water. By following these installation steps, you can minimize the risk of issues such as leaks, blockages, and inefficient water distribution.

Maintenance of Risers in Plumbing

Maintenance is crucial for ensuring the longevity and efficient functioning of risers in a plumbing system. Regular inspections are essential, as they allow me to identify any signs of damage, wear, or leaks in the risers. These inspections enable me to take prompt action and prevent further damage, ensuring optimal performance.

If any issues are detected during the inspections, cleaning and repairs should be carried out promptly to prevent the escalation of problems. Cleaning not only removes any buildup or debris that could potentially block the risers but also helps maintain water quality and prevent corrosion. Repairs should be done promptly to address any damage and restore the functionality of the risers.

I ensure that risers are inspected at regular intervals, considering factors such as the type of riser and the operating conditions. This proactive approach to maintenance helps me identify and address potential issues before they worsen. It is important to note that neglected maintenance can lead to severe problems like leaks, blockages, and corrosion, compromising the overall performance and integrity of the plumbing system.

As part of my maintenance routine, I make use of plumbing riser diagrams. These diagrams are valuable tools that provide a visual representation of the system. By consulting these diagrams, I can easily identify the position and connections of the risers, which aids in troubleshooting and identifying potential issues. Plumbing riser diagrams are an indispensable resource, enabling efficient and effective maintenance of the plumbing system.

Source Links

- https://buildops.com/commercial-construction/plumbing-riser-diagrams/

- https://www.althoffindcommercial.com/blog/plumbing-service/risers-what-they-are-how-to-know-they-need-replacement/

- https://theplumbingteam.co.uk/riser-plumbing-explained/

- Investing Wisely: How Windows & Doors in Boost Property Value and Financial Health - April 24, 2025

- The Financial Impact of Personal Injuries: Why Legal Help Matters for Business Owners - April 16, 2025

- The Hidden Financial Costs of Domestic Assault: What Business Owners Need to Know - April 16, 2025