Understanding FNPT in Plumbing – Your Quick Guide

Did you know that FNPT is an essential term in the world of plumbing, but do you know what it actually means? If you’ve ever come across this acronym and wondered what it stands for and its significance in plumbing systems, you’re about to find out.

Key Takeaways:

- FNPT stands for Female National Pipe Tapered.

- It refers to the female end of a threaded connection in plumbing.

- FNPT fittings have a tapered thread design for secure and leak-proof connections.

- Thread sealants, such as Teflon tape, are often used to ensure a fully sealed connection.

- Understanding FNPT is crucial for anyone working with plumbing systems.

How are leakproof seals achieved and maintained in pipe thread joints?

When it comes to achieving leakproof seals in pipe thread joints, the key lies in the compression and sealing of the tapered threads. Whether you’re working with FNPT fittings or other threaded connections in plumbing, ensuring a secure seal is essential to prevent leaks and maintain the efficiency of the system.

During the tightening process of FNPT fittings, the compression in the threads occurs within the first few turns of the internal thread. As the fittings are tightened further, the material from both the male and female threads deform and interlock with each other. This deformation creates full thread contact, minimizing the potential for any spiral leakages to occur.

It’s important to note that variations in thread forms can exist due to different manufacturing processes. In some cases, especially with plastic pipe threads, additional measures may be necessary to ensure leakproof seals. This is where the use of thread sealants becomes crucial.

Thread sealants, such as Teflon tape or liquid sealants, can be applied to all plastic pipe threads to block any potential spiral leak paths. These sealants fill in the minute spaces between the threads, providing an extra layer of protection and ensuring a pressure-tight seal.

By understanding the importance of compression, sealing, and the application of appropriate thread sealants, you can achieve and maintain leakproof seals in pipe thread joints, ensuring the longevity and effectiveness of your plumbing system.

In the table below, you’ll find a summary of the key steps to achieving and maintaining leakproof seals in pipe thread joints:

| Steps | Actions |

|---|---|

| 1 | Tighten FNPT fittings, focusing on the first few turns of the internal thread for initial compression. |

| 2 | Continue tightening the fittings to ensure full thread contact, allowing the material from both the male and female threads to deform into each other. |

| 3 | Apply Teflon tape or liquid sealants on all plastic pipe threads to block potential spiral leak paths. |

| 4 | Inspect the joints for any signs of leakage, such as drips or wet spots, and make any necessary adjustments or reapplications of thread sealants. |

| 5 | Maintain regular inspections and maintenance of pipe thread joints to ensure long-lasting leakproof seals. |

Understanding different pipe thread types and their uses

When it comes to plumbing, there are several different pipe thread types that serve various purposes. Understanding these thread types is essential for ensuring proper connections and leakproof seals in your plumbing system. In this section, I will dive into the details of the different pipe thread types commonly used in plumbing and their specific applications.

NPT (National Pipe Tapered)

The NPT thread type is one of the most widely used pipe thread types in plumbing. It features a tapered design, which means that the threads gradually narrow down towards the end. This tapering helps create a tight and secure connection when joining two NPT fittings. NPT threads are commonly used for low to medium pressure plumbing applications, including water supply lines, drainage systems, and gas lines.

NPTF (National Pipe Taper Fuel)

NPTF threads are an enhanced version of NPT threads. They are also tapered, but with a finer thread pitch and a modified crest shape. This makes NPTF threads more suitable for applications where a higher level of sealing is required. NPTF threads are considered dryseal threads, meaning they have a better chance of achieving leakproof seals without the need for additional thread sealants. These threads are commonly used in fuel systems and hydraulic applications.

BSP (British Standard Pipe)

The BSP thread type is commonly used in European and international plumbing systems. Unlike NPT and NPTF threads, BSP threads have a parallel design, which means that the threads run parallel to each other without tapering. BSP threads are commonly used in high-pressure plumbing applications, such as water mains, irrigation systems, and hydraulic systems.

To help you visualize the differences between these pipe thread types, here’s a table summarizing their key characteristics and applications:

| Thread Type | Design | Application |

|---|---|---|

| NPT | Tapered | Low to medium pressure plumbing systems |

| NPTF | Tapered, enhanced sealing | Fuel systems, hydraulic applications |

| BSP | Parallel | High-pressure plumbing systems |

As you can see, each pipe thread type has its own unique design and application. It’s important to choose the right thread type for your specific plumbing needs to ensure proper connections and leakproof seals.

The importance of thread sealants in NPT fittings

Thread sealants play a crucial role in ensuring leakproof seals in NPT fittings. While NPT fittings have a tapered design that provides a secure fit, they may still require additional thread sealants to block any potential spiral leak paths.

Common thread sealants used in plumbing include Teflon tape and pipe joint compounds. These sealants fill in the minute spaces between the threads, preventing leakage and ensuring a tight connection.

It is important to apply the sealants carefully to avoid system contamination and to follow specific guidelines for plastic thread forms to prevent chemical attack on plastic materials.

When using thread sealants in NPT fittings, it is essential to choose the right sealant for the job. Teflon tape is a popular choice and provides an effective seal for most applications. Pipe joint compounds, on the other hand, offer a more durable and long-lasting solution. The choice between these two options depends on factors such as the type of material used, the temperature and pressure conditions, and the specific requirements of the application.

Additionally, proper installation techniques are crucial to ensure the effectiveness of thread sealants. When applying Teflon tape, it should be wrapped in the direction of the thread, starting from the first thread and overlapping by about half. For pipe joint compounds, a thin and even layer should be applied to the male threads, ensuring full coverage without excess material.

By using thread sealants in NPT fittings, you can achieve leakproof seals and minimize the risk of costly leaks and damages. These sealants provide an extra layer of protection and ensure the reliability and efficiency of your plumbing system.

Benefits of Thread Sealants in NPT Fittings:

- Prevent leaks and potential spiral leakages

- Create a tight and secure connection

- Minimize the risk of system contamination

- Protect against chemical attack on plastic materials

- Ensure the longevity and durability of the plumbing system

| Thread Sealant Type | Features | Applications |

|---|---|---|

| Teflon Tape | – Easy to use with clean installation – Provides a reliable seal – Suitable for most applications |

– Water supply lines – Drainage systems – HVAC systems – Natural gas lines – Plumbing fixtures and fittings |

| Pipe Joint Compounds | – Durable and long-lasting – Withstand high temperatures and pressures – Resistant to chemicals and solvents – Provides enhanced sealing |

– Pipe connections in industrial settings – High-pressure hydraulic systems – Gas distribution lines – Steam pipes |

Materials used in NPT fittings and their suitability

NPT fittings are available in a range of materials to meet the specific requirements of various applications. The choice of material depends on the demands of the application, fluid compatibility, and environmental factors. Let’s explore the common materials used in NPT fittings and their suitability:

1. Brass

Brass fittings are widely used in NPT fittings due to their machinability, strength, and resistance to corrosion and heat. Brass fittings provide reliable performance and durability, making them suitable for a wide range of plumbing applications. Their excellent resistance to dezincification makes them an ideal choice for environments with harsh water conditions.

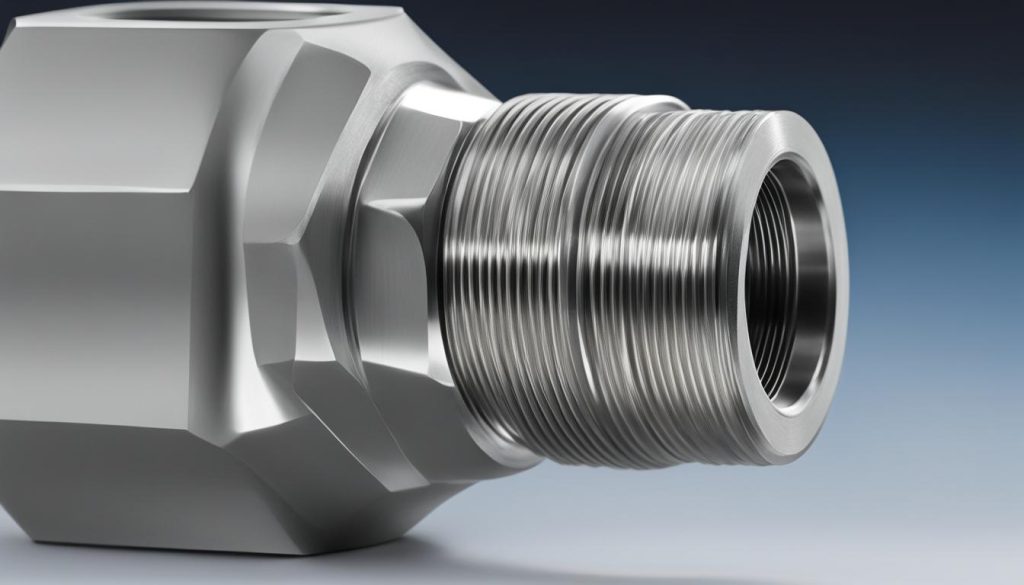

2. Stainless Steel

Stainless steel fittings offer superior strength and exceptional resistance to corrosion and high temperatures, making them ideal for demanding environments. They are commonly used in industries where durability and reliability are paramount, such as marine, oil and gas, and chemical processing. Stainless steel fittings ensure long-lasting performance and can withstand extreme conditions.

3. Steel

Steel fittings are known for their cost-effectiveness and durability. While they may lack the same level of corrosion resistance as brass or stainless steel, they are still widely used in various plumbing applications. Steel fittings are particularly suitable for applications where cost is a significant factor and corrosion risk is relatively low.

4. Plastic

Plastic fittings, typically made from PVC (Polyvinyl Chloride) or PTFE (Polytetrafluoroethylene), are lightweight and corrosion-resistant. They offer excellent chemical resistance and are ideal for various plumbing applications. Plastic fittings are particularly suitable for applications where weight reduction is important or in environments where metal fittings may be susceptible to corrosion.

It is important to consider these material options when selecting NPT fittings to ensure compatibility with the specific application requirements. Here is a visual representation of the suitability of different materials for NPT fittings:

| Material | Suitability |

|---|---|

| Brass | High |

| Stainless Steel | High |

| Steel | Moderate |

| Plastic | Moderate |

As shown in the table, brass and stainless steel offer high suitability for a wide range of applications, while steel and plastic provide moderate suitability based on various factors.

Now that we have explored the materials used in NPT fittings and their suitability, we can move on to understanding the different types of NPT fittings and their applications.

Types of NPT fittings and their applications

NPT fittings come in various types, including male NPT, female NPT, and NPTF fittings. These fittings are essential components in plumbing systems, providing secure connections for the smooth flow of fluids or gases. Let’s explore each type and their applications in more detail:

1. Male NPT fittings

Male NPT fittings have threads on the outside and are designed to make leak-proof connections. They are commonly used to connect with female NPT fittings or other male fittings. The tapered threads ensure a strong and secure connection, minimizing the risk of leakage. Male NPT fittings find applications in plumbing and HVAC systems, water supply lines, and various industrial processes.

2. Female NPT fittings

Female NPT fittings have threads on the inside and are designed to receive male NPT fittings. These fittings provide a secure connection and play a crucial role in plumbing systems. They are commonly used for joining pipes, valves, and other components in residential, commercial, and industrial plumbing applications. Female NPT fittings accommodate male NPT fittings, ensuring a tight and sealed joint.

3. NPTF fittings

NPTF fittings, also known as dryseal fittings, are similar to NPT fittings but offer enhanced sealing properties. They are designed to provide leak-proof connections without the need for additional sealants. NPTF fittings are commonly used in plumbing systems, hydraulic systems, and pneumatic applications. These fittings ensure reliable connections, even in low-pressure environments.

NPT fittings are widely used across various industries, including oil and gas, manufacturing, automotive, construction, marine, agriculture, and food and beverage. They are crucial for ensuring the smooth flow of fluids or gases in hydraulic systems. The versatility and reliability of NPT fittings make them an integral part of modern plumbing systems.

As shown in the image above, NPT fittings find applications in various plumbing systems, including water supply lines, drainage systems, and gas lines.

An overview of NPT fittings and their significance in plumbing systems

NPT fittings are of utmost importance in plumbing systems as they provide secure and leak-proof connections, ensuring the smooth flow of fluids and gases. With their tapered thread design, NPT fittings create a tight seal, guaranteeing the efficiency and reliability of hydraulic systems. To achieve leakproof seals and prevent potential spiral leakages, thread sealants like Teflon tape or pipe joint compounds are commonly used with NPT fittings.

The choice of materials for NPT fittings is critical and depends on specific application requirements, including factors such as corrosion resistance and fluid compatibility. Common materials used in NPT fittings include brass, stainless steel, steel, and plastic. Each material has its unique characteristics, making it suitable for different environments and applications. For example, brass fittings offer corrosion resistance and high strength, while stainless steel fittings excel in harsh environments with their exceptional resistance to corrosion and high temperatures. Steel fittings, on the other hand, provide a cost-effective and durable option.

NPT fittings are extensively used across various industries, including oil and gas, manufacturing, automotive, plumbing, and construction. Their importance in modern plumbing systems cannot be overstated, as they ensure the smooth operation and functionality of hydraulic systems. Whether it’s maintaining water supply, drainage, or gas lines, NPT fittings play a vital role in creating reliable connections, establishing optimal flow, and preventing leaks or disruptions in plumbing systems.

- Investing Wisely: How Windows & Doors in Boost Property Value and Financial Health - April 24, 2025

- The Financial Impact of Personal Injuries: Why Legal Help Matters for Business Owners - April 16, 2025

- The Hidden Financial Costs of Domestic Assault: What Business Owners Need to Know - April 16, 2025