Did you know that improper vent sizing is one of the leading causes of plumbing issues in residential homes? In fact, a study conducted by the Canadian Plumbing Association found that over 70% of plumbing problems can be traced back to incorrectly sized vent pipes.

When designing a plumbing venting system, it’s crucial to ensure that the vent pipes have the optimal diameter. This guide will provide essential information on determining the correct vent size for your plumbing system, helping you avoid common issues and maintain a properly functioning system.

Key Takeaways:

- Improper vent sizing is a leading cause of plumbing problems in residential homes.

- Our guide will provide essential information and tips on vent sizing for your plumbing venting system.

- Proper vent installation and compliance with local codes are crucial for a well-functioning plumbing system.

- By following the guidelines in this guide, homeowners can ensure the efficiency and longevity of their plumbing venting system.

Understanding Plumbing Venting Requirements

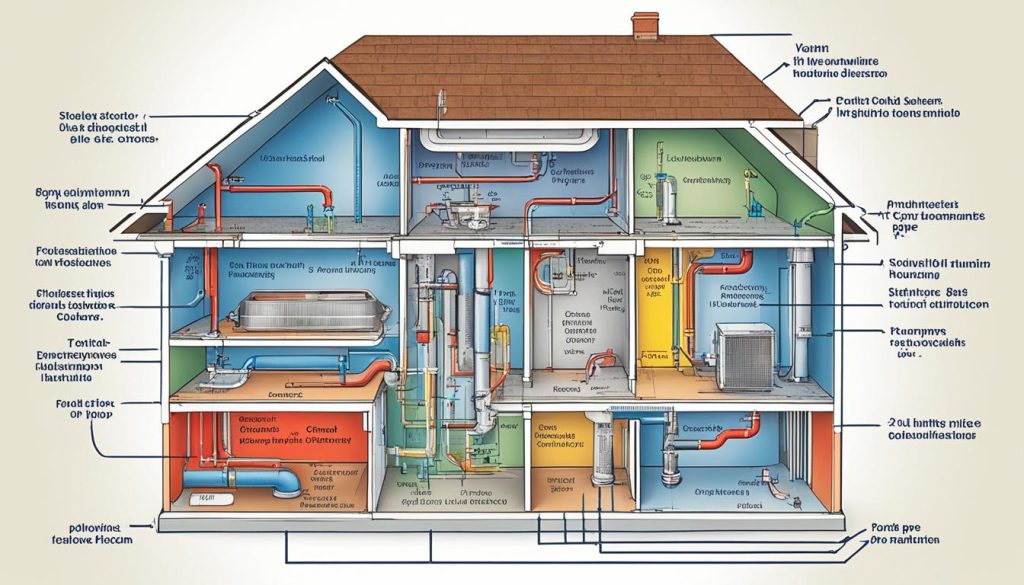

When designing a plumbing venting system, it’s crucial to understand and comply with the specific requirements outlined by the plumbing code. In many jurisdictions, the Uniform Plumbing Code (UPC) is followed to ensure proper venting system design and vent stack size. Adhering to the code is important not only for compliance but also to prevent issues such as freezing or sewer gas odors.

The UPC specifies that the vent stack should be no less than half the size of the building drain. Since most building drains have a diameter of 3 inches, the vent stack should be at least 1.5 inches in diameter. This size requirement ensures sufficient airflow and proper venting throughout the plumbing system.

Proper vent pipe installation is also essential for venting code compliance. The vent stack should extend vertically through the roof and terminate above the roofline to prevent backdrafting and the entry of rainwater or debris. Additionally, horizontal vent pipes should be installed with the correct slope to allow for proper drainage and avoid the accumulation of fluids.

By following the plumbing code’s venting requirements and installing the appropriate vent stack size and pipe, you can ensure a well-designed and code-compliant plumbing venting system that operates efficiently and effectively.

Different Types of Vents in Plumbing Systems

Plumbing venting systems utilize various types of vents to ensure proper airflow and venting. Understanding these different types can help you design and implement an efficient plumbing system. Let’s explore some common vent options:

1. Vent Pipe Size

One of the essential considerations in plumbing venting is the vent pipe size. The diameter of the vent pipe affects the effectiveness of the venting system. It’s crucial to choose the appropriate vent pipe size based on the specific plumbing requirements. Common vent pipe sizes include 2-inch, 3-inch, and 4-inch diameters.

2. 3-Inch Vent Stacks

3-inch vent stacks are commonly used in plumbing systems to provide venting for various fixtures. These vertical pipes allow air to enter the drainage system and equalize pressure, preventing siphoning and ensuring proper drainage. Vent stacks are usually connected to the building drain and extend through the roof.

3. Secondary Stacks

Secondary stacks, also known as branch vents or wet vent pipes, are additional vertical pipes connected to the main vent stack. They provide venting for fixtures located far away from the main vent stack. Secondary stacks allow for proper ventilation and prevent drainage issues.

4. Revent Pipe

A revent pipe, also called a branch revent, is a specialized vent pipe that connects to a wet vent. It facilitates proper venting for fixtures such as toilets and sinks that are connected to a wet vent. Revent pipes ensure optimal venting and prevent air pressure imbalances in the plumbing system.

5. Wet Vent

A wet vent is a type of venting system where a single pipe both acts as a drain pipe and a vent pipe. It serves as both the drain and vent for one or more fixtures. Wet venting is commonly used in bathrooms, where a single pipe handles drainage and venting needs for the toilet, sink, and bathtub or shower.

6. Air Admittance Valve (AAV)

An air admittance valve (AAV) is a mechanical device used to vent plumbing systems. It is a one-way valve that allows air to enter the drainage system but prevents sewer gases from escaping. AAVs are installed in accessible locations, such as under sinks or behind toilets, to provide additional venting when traditional venting methods are not feasible.

Understanding these different types of vents in plumbing systems is key to designing and implementing an efficient and compliant venting system. The appropriate selection and installation of vent pipes, stacks, and other venting components ensure smooth drainage, prevent sewer odors, and maintain the integrity of your plumbing system.

Factors to Consider for Vent Sizing

Calculating the proper vent size is a crucial step in designing an efficient plumbing venting system. Several factors need to be taken into consideration to determine the optimal plumbing vent size and vent pipe diameter.

- Fixture Unit Load: The fixture unit load refers to the number of plumbing fixtures and their drainage capacity within a particular branch or stack. The higher the fixture unit load, the larger the vent size required to handle the drainage flow.

- Drainage Pipe Length: The length of the drainage pipe affects the pressure drop and the need for additional vent sizing. Longer drain pipes may require larger vent pipe diameters to compensate for pressure differences.

- Vertical Stack Height: The height of the vertical stack is crucial for determining the vent pipe diameter. Tall vertical stacks require larger vent sizes to prevent airlock and maintain proper airflow.

- Distance to the Vent Outlet: The distance between a plumbing fixture and the vent outlet can impact the vent size calculation. Longer distances may require larger vent diameters to ensure sufficient airflow.

- Number of Fixtures Connected: The number of fixtures connected to the drainage system affects the demand for proper vent sizing. More fixtures connected may require larger vent sizes to maintain adequate airflow and prevent clogs.

By considering these factors and using appropriate vent sizing calculations, you can ensure that your plumbing venting system meets the required standards and provides efficient airflow to prevent plumbing issues.

Factors to Consider for Vent Sizing

| Factors | Considerations |

|---|---|

| Fixture Unit Load | Higher fixture unit load requires a larger vent size. |

| Drainage Pipe Length | Longer drain pipes may require larger vent pipe diameters. |

| Vertical Stack Height | Tall vertical stacks require larger vent sizes. |

| Distance to the Vent Outlet | Longer distances may require larger vent diameters. |

| Number of Fixtures Connected | More connected fixtures may require larger vent sizes. |

Ensuring Proper Vent Installation

Proper installation of vent pipes is crucial for a well-functioning plumbing system. It not only ensures efficient drainage but also prevents issues such as sewer gas odors and water damage. To guarantee compliance with venting codes and regulations, follow these essential practices:

- Observe Proper Vent Pipe Sizing: Choose the correct vent pipe size to meet the specifications outlined in local plumbing codes. By adhering to the required dimensions, you can maintain proper airflow and prevent potential plumbing system malfunctions.

- Use Approved Materials: Utilize vent pipes made of high-quality materials that are approved for plumbing applications. PVC, ABS, and cast iron are common choices that meet regulatory standards and provide durability and longevity.

- Avoid Improper Sloping: Ensure that vent pipes slope smoothly towards the drainage stack. This allows for efficient air movement and minimizes the risk of blockages or stagnant water.

- Maintain Proper Vent Pipe Positioning: Position vent pipes vertically and as close to the plumbing fixtures as possible. This setup promotes the natural flow of air and prevents clogs caused by debris or water accumulation.

- Insulate in Cold Climates: In regions with freezing temperatures, insulate vent pipes to prevent ice buildup and blockage. This precautionary measure safeguards against potential plumbing disruptions during winter months.

- Secure Vent Pipes Properly: Fasten vent pipes securely to ensure stability and prevent movement over time. Use appropriate supports and brackets to maintain proper alignment and angle.

- Follow Manufacturer Instructions: Adhere to the manufacturer’s guidelines and specifications when installing vent pipes. This includes recommendations for joint connections, sealing, and any additional instructions specific to the venting system or materials used.

By following these best practices for vent pipe installation, you can ensure both the functionality and compliance of your plumbing venting system. Consult with a professional plumber if necessary to guarantee proper installation and adherence to local building codes.

Importance of Proper Vent Sizing

When it comes to plumbing systems, proper vent sizing is crucial for efficient operation. The size of the plumbing vent plays a significant role in maintaining the overall performance and functionality of the system.

Undersized vents can cause various issues, such as slow drainage, gurgling sounds, and unpleasant sewer smells. These problems can disrupt the smooth flow of wastewater and affect the entire plumbing system.

On the other hand, oversized vents can lead to excessive airflow, which can result in a reduced water seal in traps. This can allow sewer gases to escape, leading to unwanted odors in your home.

To ensure a well-functioning and code-compliant plumbing venting system, it is essential to select the appropriate vent pipe size and follow proper installation practices. By doing so, homeowners can prevent common plumbing problems and maintain a smoothly running system.