Essential Types of Pipe Fitting Explained

Did you know that pipe fittings are crucial components of plumbing systems used in various industries and applications? These fittings enable proper connection and termination of pipes, ensuring seamless flow and function. With the wide range of pipe fittings available, understanding their types, materials, sizes, and dimensions is essential for effective plumbing solutions.

In this article, I will explore the essential types of pipe fittings, their functions, selection criteria, and more. Whether you are a plumber, a DIY enthusiast, or simply curious about how pipes are connected, this article will provide valuable insights into the world of pipe fittings.

Key Takeaways

- Pipe fittings are crucial components of plumbing systems used in various industries and applications.

- Understanding the different types, materials, sizes, and dimensions of pipe fittings is essential for effective plumbing solutions.

- Elbows are used to change the direction of flow in a plumbing system.

- Couplings prevent leakages in broken or damaged pipes.

- Unions allow for easy removal of pipes and join pipes made of different materials.

- Adapters are used to connect pipes with different ends or increase the length of pipes.

- Nipples act as connectors between two male-threaded fittings.

- Additional pipe fittings such as reducers, tees, crosses, flanges, caps, and plugs play crucial roles in plumbing systems.

Elbows: Changing the Direction of Flow

Elbows are essential pipe fittings used in plumbing systems to alter the direction of flow. They come in two standard types: the 90-degree elbow and the 45-degree elbow.

The 90-degree elbow is commonly employed in various industries such as plumbing, electronic and chemical industrial pipeline networks, agriculture, and solar-energy facilities. It is ideal for connecting hoses to water pumps, valves, and drains.

On the other hand, the 45-degree elbow is predominantly used in water supply facilities, air-conditioning pipelines, and garden production.

| Type | Plumbing Applications | Materials |

|---|---|---|

| 90-degree elbow | Connect hoses to water pumps, valves, and drains | ABS plastic, PVC, chrome-plated brass, CPVC, stainless steel, malleable (galvanized and black), copper |

| 45-degree elbow | Water supply facilities, air-conditioning pipelines, garden production | ABS plastic, PVC, chrome-plated brass, CPVC, stainless steel, malleable (galvanized and black), copper |

Plumbing Applications of Elbow Fittings

- In the plumbing industry, elbow fittings are widely used to change the direction of pipes, optimize water flow, and improve overall system efficiency.

- They are crucial components in electronic and chemical industrial pipeline networks for redirecting the flow of various liquids and gases.

- Agricultural irrigation systems utilize elbow fittings to control the direction of water flow, ensuring efficient water distribution.

- Elbows are essential in solar-energy facilities, where they are used in thermal collectors and solar hot water systems to redirect the flow of heat transfer fluids.

Couplings: Preventing Leakages in Pipes

Couplings are essential pipe fittings used to prevent leakages in broken or damaged pipes. They play a crucial role in connecting two pipes of the same diameter, ensuring a secure and reliable joint. Couplings are widely used in various plumbing applications to maintain the integrity and efficiency of the overall system.

Types of Coupling Fittings

There are two main types of couplings commonly used in plumbing applications:

- Regular Coupling:

A regular coupling is a popular choice for connecting two pipes and preventing further leakages. It features rubber seals or gaskets on both sides, ensuring a tight and leak-proof connection. The rubber seals help to create a secure bond between the pipes, minimizing the risk of leaks or water damage.

- Slip Coupling:

A slip coupling is specifically designed to repair damaged lengthy pipes. It consists of two pipes inserted inside the fitting, allowing for easy adjustment and repair without the need for extensive pipe cutting or replacement. Slip couplings are particularly useful in situations where the damaged section of the pipe needs to be removed and replaced without disrupting the entire plumbing system.

Materials for Coupling Fittings

Couplings are available in various materials to suit different plumbing requirements. The choice of material depends on factors such as the type of pipes being connected, the nature of the plumbing application, and budget considerations. Common materials used for coupling fittings include:

| Material | Description |

|---|---|

| ABS | A durable and lightweight thermoplastic material commonly used in residential and commercial plumbing systems. |

| Brass | A corrosion-resistant alloy of copper and zinc that offers excellent strength and durability. |

| Copper | A versatile and reliable material known for its excellent heat and electrical conductivity. |

| Chrome-Plated Brass | Brass fittings coated with a layer of chrome for enhanced aesthetics and corrosion resistance. |

| CPVC | A durable and heat-resistant material often used for hot water plumbing applications. |

| PVC | A lightweight and cost-effective material suitable for various non-pressure plumbing systems. |

| Malleable (Galvanized and Black) | Iron fittings that offer high strength and durability, commonly used in industrial applications. |

| Stainless Steel | A corrosion-resistant alloy that provides excellent durability and longevity in demanding plumbing environments. |

When selecting coupling fittings, it’s important to consider the compatibility of the materials with the pipes being connected and the specific requirements of the plumbing application.

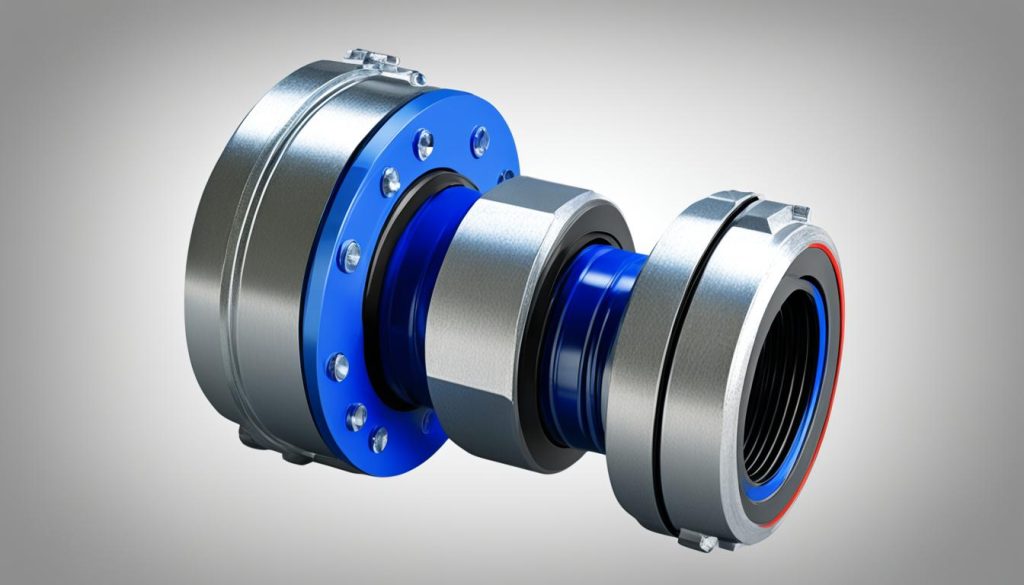

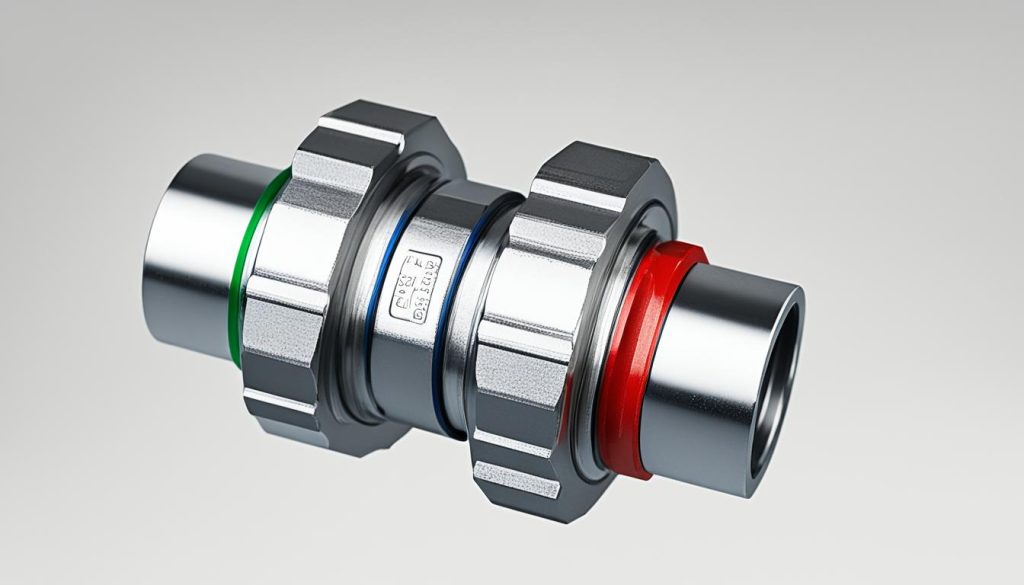

Union: Similar to Coupling with Easy Removal

Union fittings serve a similar function as couplings in plumbing applications, but with one key advantage – they can be easily removed at any time. This makes union fittings a convenient choice when regular maintenance or repairs are required.

One of the primary uses of union fittings is to join pipes made of different materials. This is particularly important in plumbing systems to prevent galvanic corrosion, which occurs when dissimilar metals come into contact with each other.

Union fittings typically consist of a nut, female, and male-ended threads. The nut is tightened or loosened to securely join or disconnect the pipes. This ease of removal allows for quick disassembly and reassembly, reducing downtime during repairs or modifications.

Dielectric Unions

A specific type of union fitting known as a dielectric union is used to join pipes made of different materials specifically to prevent galvanic corrosion. The dielectric union includes a plastic or rubber sleeve that separates the dissimilar metals, preventing direct contact and the resulting corrosion.

Dielectric unions are commonly used in plumbing systems where copper pipes are connected to galvanized steel pipes or brass fittings. By using a dielectric union, the risk of galvanic corrosion is significantly reduced, prolonging the lifespan of the plumbing system.

| Type of Union Fitting | Materials |

|---|---|

| Brass Union | Brass, Copper, Chrome-plated Brass, Malleable (Galvanized and Black), PVC, CPVC, Stainless Steel |

| Copper Union | Copper, Chrome-plated Brass, Malleable (Galvanized and Black), PVC, CPVC, Stainless Steel |

| Steel Union | Malleable (Galvanized and Black), PVC, CPVC, Stainless Steel |

| PVC/CPVC Union | PVC, CPVC, Stainless Steel |

Adapters: Connecting Pipes with Different Ends

In plumbing systems, adapters play a crucial role in connecting pipes with different ends or increasing the length of pipes. These fittings provide an easy and efficient solution, eliminating the need for extensive setup.

Adapters are designed to make the ends of the pipes either male or female threaded, depending on the specific requirements of the connection. This versatility allows for seamless integration between pipes of varying sizes and types.

Commonly used in various plumbing applications, adapters find particular significance when working with PVC and copper pipes. Their compatibility with different materials makes them highly versatile and reliable in diverse plumbing setups.

When it comes to choosing adapter fittings, there is a wide range of materials available, each offering distinct advantages in different situations. Here are some common materials used for adapter fittings:

- ABS

- CPVC

- Copper

- Malleable (galvanized and black)

- PVC

- Brass

- Stainless steel

These materials are carefully selected to ensure durability, corrosion resistance, and compatibility with various plumbing systems.

With their ability to connect pipes with different ends and facilitate smooth transitions, adapters are a valuable asset in any plumbing project.

| Material | Advantages |

|---|---|

| ABS | Lightweight and easy to install |

| CPVC | Excellent chemical resistance |

| Copper | Highly durable and corrosion-resistant |

| Malleable (galvanized and black) | Strong and versatile |

| PVC | Cost-effective and easy to work with |

| Brass | Sturdy and resistant to high temperatures |

| Stainless Steel | Exceptionally durable and corrosion-resistant |

Choose the right adapter fitting and material for your specific plumbing needs to ensure reliable and efficient pipe connections.

Nipple: Short Butt for Pipe Connection

In plumbing systems and hoses, nipple fittings play a crucial role as connectors between two other fittings with male threads. These short sections of pipe are widely used in various plumbing applications, ensuring secure and reliable pipe connections. One specific type of nipple fitting is the close nipple, which features continuous threading for enhanced stability.

Nipple fittings can be made from a variety of materials to suit different plumbing requirements. Common materials used for nipple fittings include brass, chrome-plated brass, malleable (galvanized and black) iron, PVC, copper, and stainless steel. Each material offers its own unique set of benefits in terms of durability, corrosion resistance, and compatibility with different pipe systems.

When selecting nipple fittings for your plumbing project, it’s essential to consider the specific materials, dimensions, and thread sizes required for a proper fit. Consulting with a reputable plumbing supplier or manufacturer can help ensure that you choose the right nipple fittings for your needs.

Reducer, Tee, Cross, Flange, Caps & Plugs: Additional Pipe Fitting Types

In addition to the types of pipe fittings we have already discussed, there are several other fittings that are essential for plumbing systems. These additional fittings include reducers, tees, crosses, flanges, caps, and plugs. Each of these fittings serves a specific purpose and is used in various plumbing applications.

A pipe reducer is used to decrease the flow size of a pipe from a larger diameter to a smaller diameter. This is often necessary when connecting pipes of different sizes to ensure a proper fit and smooth flow. Pipe tees, on the other hand, have one inlet and two outlets arranged at a 90-degree angle. They are commonly used to connect two pipes, allowing the flow to be split or combined.

Pipe crosses are fittings that have four openings in four major directions. They are frequently used in fire sprinkler systems where multiple pipes need to intersect. Pipe flanges provide a secure and leak-proof connection between pipes, valves, and other components. They are known for their easy cleaning and inspection capabilities.

Finally, caps and plugs are used to close off the ends of pipes temporarily or permanently. This is important when pipes need to be sealed temporarily during maintenance or permanently when they are no longer in use. These additional pipe fittings are available in various materials, including PVC, brass, ABS, malleable (galvanized and black), and stainless steel, ensuring compatibility with different plumbing systems and applications.

Source Links

- http://www.thepipefittings.com/pipe-fittings-types.html

- https://www.homedepot.com/c/ab/types-of-pipe-fittings/9ba683603be9fa5395fab90421ffd03

- https://blackhawksupply.com/blogs/articles/pipe-fittings-guide-definition-types-applications

- Investing Wisely: How Windows & Doors in Boost Property Value and Financial Health - April 24, 2025

- The Financial Impact of Personal Injuries: Why Legal Help Matters for Business Owners - April 16, 2025

- The Hidden Financial Costs of Domestic Assault: What Business Owners Need to Know - April 16, 2025