When it comes to creating secure and semi-permanent connections between pipes, pipe unions are an essential component. These pipe fittings allow for easy assembly and disassembly without causing any deformation to the pipes. In fact, pipe unions are commonly used in applications such as fire protection piping systems, water and wastewater piping systems, non-critical process piping systems, and plumbing applications.

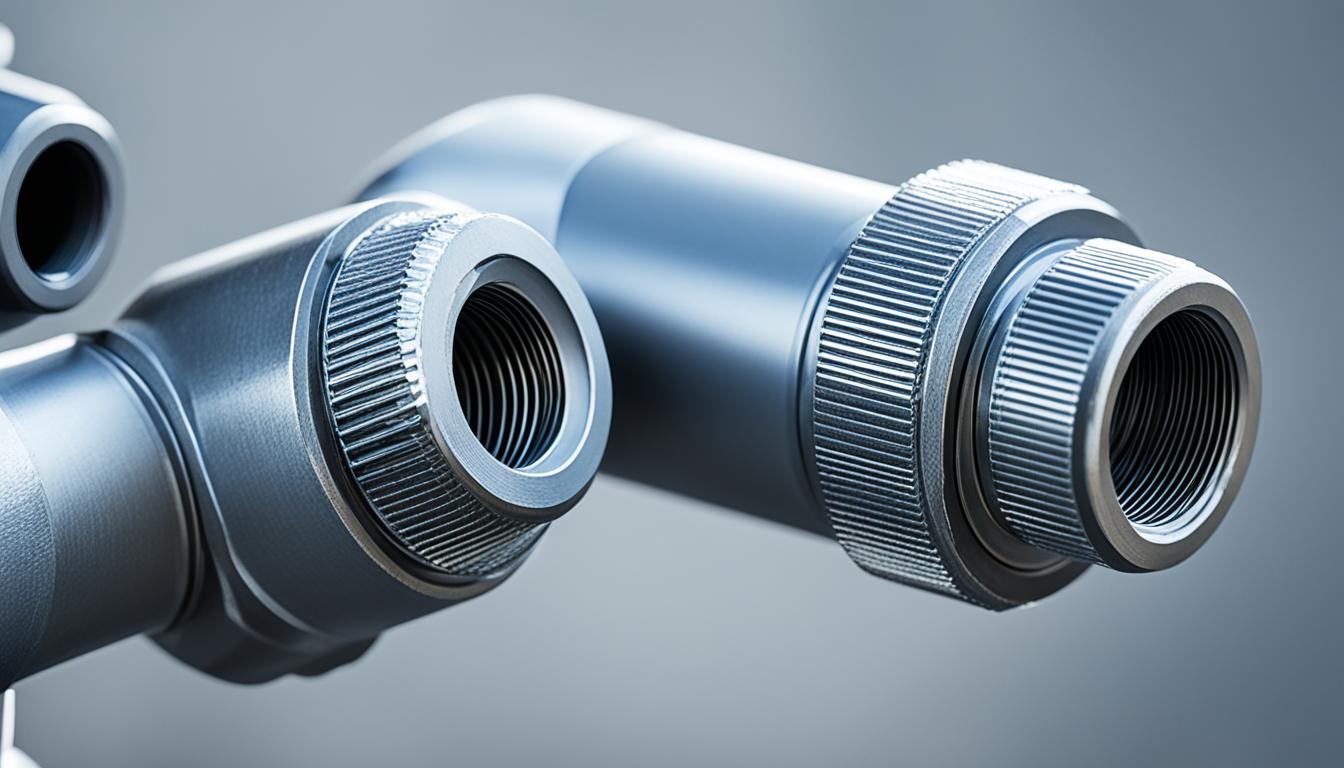

A pipe union consists of a male end, a female end, and a nut that seals the joint. The nut applies the necessary pressure to ensure a tight seal. With various sizes available, ranging from 1/8 inches to 4 inches, pipe unions can accommodate different pipe dimensions.

There are two main types of pipe unions: ground joint unions and flange unions. Ground joint unions have an angled cut to increase the joint surface area, while flange unions use flanges to hold two pipes together. Pipe unions can be threaded or socket welded, and they are made from materials such as carbon steel, stainless steel, cast iron, copper, brass, and plastics.

Overall, pipe unions offer a secure and reliable solution for connecting pipes, allowing for easy installation, disassembly, and positive sealing.

Key Takeaways:

- Pipe unions are essential pipe fittings used to create secure and semi-permanent connections between pipes.

- They allow for easy assembly and disassembly without causing any deformation to the pipes.

- Pipe unions are commonly used in various applications such as fire protection piping systems, water and wastewater piping systems, non-critical process piping systems, and plumbing applications.

- There are two main types of pipe unions: ground joint unions and flange unions.

- Pipe unions can be threaded or socket welded, and they are made from materials such as carbon steel, stainless steel, cast iron, copper, brass, and plastics.

Types of Pipe Fittings and Connections

In addition to pipe unions, there are various other types of pipe fittings used in piping systems. These fittings play a crucial role in changing the direction of flow, adapting or reducing sizes, connecting different components, and controlling the flow of fluids. Understanding the different types of pipe fittings is essential for ensuring the proper functioning and maintenance of piping systems.

Elbows

Elbows are pipe fittings that allow for directional changes in a piping system. They are typically available in 45-degree and 90-degree angles, although customized angles can also be manufactured.

Tees

Tees are pipe fittings that create a T-shaped connection, allowing for the branching of a pipeline into two directions. They come in various sizes and configurations to suit different requirements.

Reducers

Reducers, as the name suggests, are pipe fittings used to reduce the size of a pipe. They provide a smooth transition between pipes of different diameters, ensuring efficient flow and preventing pressure loss.

Couplings

Couplings are pipe fittings used to connect two pipes of equal or different sizes. They offer a secure and leak-free connection, supporting easy assembly and disassembly for maintenance purposes.

Crosses

Crosses are pipe fittings that allow for the branching of a pipeline into four directions. They are commonly used in complex piping systems and provide a stable and efficient connection.

Caps

Caps are pipe fittings used to close the end of a pipe. They provide protection and prevent the entry of foreign particles into the pipe, ensuring the integrity of the system.

Swage Nipples

Swage nipples are pipe fittings used for connecting two pipes with different diameters. They feature a tapered end, allowing for easy alignment and a tight, secure connection.

Plugs

Plugs are pipe fittings used to close the end of a pipe temporarily or permanently. They are commonly used in applications where future expansion or maintenance may be required.

Bushings

Bushings are pipe fittings used to connect pipes of different sizes. They feature a male and female threaded end, ensuring a reliable and leak-free connection.

Adapters

Adapters are pipe fittings used to connect pipes of different materials or thread types. They provide a smooth transition between different components of a piping system.

Outlets

Outlets are pipe fittings used to create additional connections on an existing pipeline. They provide a convenient way to add branches or extensions to the system without affecting its integrity.

Valves

Valves are pipe fittings that regulate the flow of fluids within a piping system. They are designed to control the opening and closing of passages, allowing for precise flow control.

Flanges

Flanges are pipe fittings used to connect two pipes or valves with bolts or studs. They provide a secure and leak-free connection, facilitating easy assembly and disassembly.

Pressure Classes

Pipe fittings are available in various pressure classes, which determine their suitability for different applications. Pressure class ratings range from 150 PSI to 3000 LB, with higher ratings available for specialized applications.

Forged Carbon Steel Fittings

Forged carbon steel fittings are pipe fittings made from carbon steel through a forging process. They offer high strength, durability, and resistance to corrosion, making them suitable for demanding applications.

MSS SP-114 Fittings

MSS SP-114 fittings are pipe fittings that adhere to the guidelines set by the Manufacturers Standardization Society (MSS). They are designed to meet specific requirements and ensure the reliable performance of the piping system.

Pipe Union Fittings

Pipe union fittings play a vital role in creating secure and semi-permanent connections between pipes. With their easy assembly and disassembly features, they provide convenience without compromising the integrity of the pipes. A pipe union consists of a male end, a female end, and a nut that seals the joint, ensuring a secure connection.

The male and female ends of the pipe union fittings are threaded, allowing for a tight and reliable seal. The nut is responsible for applying the necessary sealing pressure. The threaded pipe union follows the NPT (National Pipe Tapered) standard for the male end and follows the straight thread standard for the nut.

The seating surfaces of the pipe union fittings are designed to form integral metal-to-metal or ball-to-cone connections, enhancing their positive sealing capabilities.

While pipe union fittings provide a secure connection, it is important to note that their leakage probability is higher compared to other types of pipe fittings. As a result, pipe union fittings are generally recommended for non-hazardous and non-flammable services.

Pipe union fittings are commonly used in various applications, including fire protection piping systems, water and wastewater piping systems, non-critical process piping systems with low pressure and temperatures, and plumbing applications. Their versatility and ease of installation make them a popular choice for both professionals and DIY enthusiasts.

| Application | Description |

|---|---|

| Fire protection piping systems | Used to create secure connections in fire protection systems, ensuring reliable performance in emergency situations. |

| Water and wastewater piping systems | Provide a secure connection for pipes in water supply and wastewater treatment systems, preventing leaks and maintaining efficient flow. |

| Non-critical process piping systems | Offer an easy and reliable connection method for non-critical processes, enabling efficient system maintenance and repair. |

| Plumbing applications | Used in various plumbing installations, ensuring secure and leak-free connections for sinks, toilets, showers, and other fixtures. |

With their secure connection, ease of assembly, and wide range of applications, pipe union fittings continue to be a popular choice in the plumbing and piping industries.

Types of Pipe Unions

In addition to pipe unions, there are different types of pipe unions that can be used in various applications. The two main types of pipe unions are the ground joint union and the flange union. A ground joint union has an angled cut to increase the joint surface area, while a flange union uses flanges to hold two pipes together. These unions are designed for different purposes and applications.

Depending on the joint connection, there are two types of pipe unions available:

- Threaded unions

- Socket welded unions

Industrial pipe unions are commonly made from metallic materials such as carbon steel, stainless steel, cast iron, copper, brass, nickel, alloy steel, duplex stainless steel, aluminum, and bronze. However, plastic pipe unions are also available and are generally used in plumbing services.

The choice of pipe union material depends on the specific application and requirements.

Types of Pipe Unions:

| Type of Pipe Union | Description |

|---|---|

| Ground Joint Union | An angled cut to increase the joint surface area for a secure connection. |

| Flange Union | Utilizes flanges to hold two pipes together. |

| Threaded Union | Able to create a strong and leak-resistant connection with threaded ends. |

| Socket Welded Union | Uses socket welding for a reliable and robust joint between pipes. |

| Industrial Pipe Union | Made from various metallic materials like carbon steel, stainless steel, cast iron, copper, brass, nickel, alloy steel, duplex stainless steel, aluminum, and bronze. |

| Plastic Pipe Union | Specially designed for plumbing applications, typically made of durable plastics. |

Characteristics and Applications of Pipe Unions

Pipe unions possess specific characteristics that make them highly versatile and applicable in various industries and systems. As a professional in the field, I have witnessed the numerous advantages pipe unions offer in terms of functionality, ease of installation, and cost-effectiveness.

Easy Disengagement for Quick Maintenance and Repair

One of the primary benefits of pipe unions is their ability to facilitate easy disengagement. This feature allows for quick maintenance and repair, minimizing downtime in critical systems. When unforeseen issues arise, simply disconnecting the union allows for swift access to faulty components, reducing the time and effort required for repairs.

Connect Metering and Regulating Devices

Another crucial application of pipe unions is their use in connecting metering and regulating devices. By providing a secure and leak-proof connection, unions ensure accurate measurement and control of fluid flow. This enables precise monitoring and adjustment of system parameters, enhancing overall efficiency and performance.

Easy Installation and Cost-effectiveness

Pipe unions are known for their easy installation process, saving valuable time and resources. Their convenient design allows for quick assembly and disassembly, eliminating the need for complex and time-consuming procedures. Additionally, the economical nature of pipe unions reduces labor and material costs, making them a cost-effective choice for various piping systems.

Protective System against Galvanic Corrosion

In specific applications, pipe unions serve as a protective system against galvanic corrosion. When two pipes made of different metals are connected using a pipe union, it acts as a barrier, slowing down the galvanic corrosion process caused by the interaction of dissimilar metals. This ensures the longevity and integrity of the system, minimizing the risk of costly corrosion-related damages.

However, it is essential to note that pipe unions, like any pipe fitting, have a higher probability of leakage compared to other types of connections. Various factors can contribute to leakage, including improper assembly torque, imperfections in the metal-to-metal seat, dirt accumulation, high friction in the collar threads, piping misalignment, excessive vibration, and failure of the threaded or socket weld joint.

Despite this limitation, pipe unions continue to be widely used in non-hazardous and non-flammable services across various industries due to their flexibility, ease of disengagement, and multiple applications.

| Cause | Description |

|---|---|

| Improper assembly torque of the collar | Insufficient or excessive tightening of the nut |

| Imperfections in the metal-to-metal seat | Surface irregularities affecting the sealing capability |

| Dirt on the seat | Foreign particles preventing proper sealing |

| High friction in the collar threads | Excessive resistance during assembly, impairing the sealing process |

| Piping misalignment | Deviation from proper alignment affecting sealing effectiveness |

| High vibration | Frequent oscillations leading to loosening of the union |

| Thread or socket weld failure | Weakened or damaged joint resulting in leakage |

Differences Between Pipe Unions and Pipe Couplings

When it comes to connecting pipes, two popular options you’ll come across are pipe unions and pipe couplings. While they both serve a similar purpose, there are some notable differences between the two.

Pipe couplings are used for direct pipe-to-pipe connections, where one pipe screws into another. Disassembling pipe couplings requires unscrewing all the connected pipes. On the other hand, pipe unions take a different approach. They don’t directly connect two pipe ends; instead, each pipe end screws into a third piece, known as the union itself. This unique design allows for individual pipes to be removed without unscrewing the other pipes in the system.

Another difference lies in the joining methods. Pipe couplings offer three options: threaded, butt welded, and socket welded. In contrast, pipe unions have two joining methods: threaded and socket welded. This variation in joining methods makes pipe couplings suitable for higher-pressure services like pipe racks. Meanwhile, pipe unions are more versatile and commonly used in steam trap assemblies, control valve manifolds, and other parts that require regular maintenance and repair.

It’s important to note that the cost of pipe unions is typically higher than that of pipe couplings due to their added functionality. So, when considering which option to choose, it’s essential to evaluate the specific requirements of your project.

Source Links

- https://hardhatengineer.com/pipe-fittings/

- https://whatispiping.com/pipe-union/

- https://www.buyfittingsonline.com/pipe-fittings-connections-types-piping-systems-complete-guide