FIP vs NPT Differences – Understanding Pipe Threads

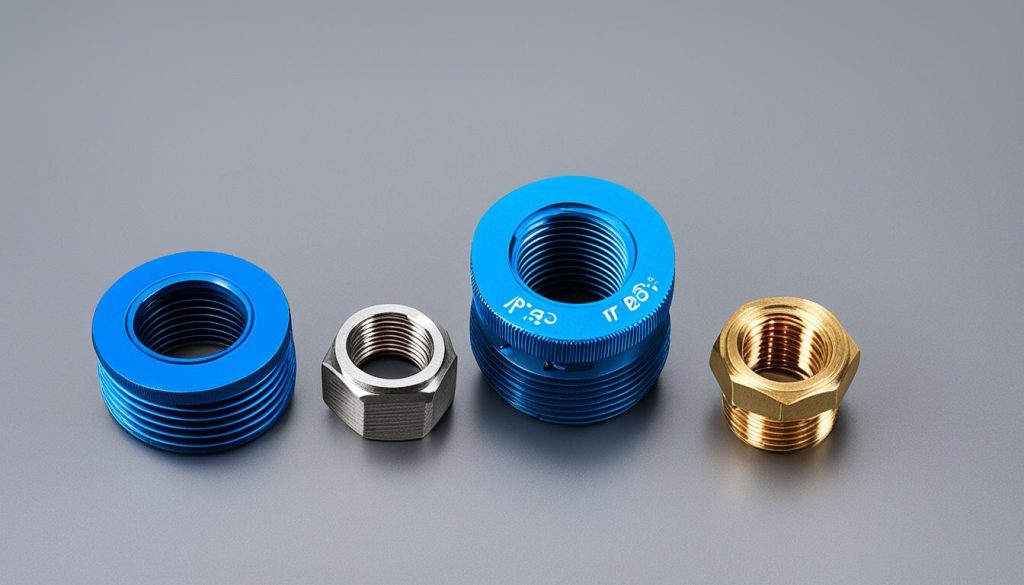

Did you know that the choice between FIP and NPT threads can greatly impact the effectiveness and compatibility of your plumbing fittings? Understanding the differences between these thread types is essential for ensuring a reliable and leak-free plumbing system.

Key Takeaways:

- FIP (female iron pipe) and NPT (national pipe tapered) are common thread types used for plumbing fittings.

- NPT threads are widely used in North America, while FIP threads are commonly found in high-pressure applications.

- NPT threads have a taper angle of 1°47′, a pitch measured in threads per inch, and a 60° angle between flat crests and troughs.

- FIP threads work in conjunction with MIP (male iron pipe) fittings and are known for their compatibility with various materials like steel, brass, and plastic.

- Choosing the right pipe fittings requires considering factors such as thread type, size, and material compatibility.

Understanding NPT Threads

When it comes to pipe threads, NPT (national pipe tapered) is the go-to choice in North America. With its versatile design and reliable performance, NPT threads are widely used in plumbing, hydraulic, and gas transportation applications.

NPT threads have a taper angle of 1°47′, a pitch measured in threads per inch, and a 60° angle between the flat crests and troughs. This unique configuration allows NPT fittings to create a tight and secure seal when connected.

NPT threads can be made from various materials, such as steel, brass, bronze, PVC, and cast iron. This versatility makes them suitable for a wide range of applications, from residential plumbing systems to heavy-duty industrial projects.

Benefits of NPT Threads:

- Reliable sealing properties

- Compatibility with a variety of materials

- Wide range of applications

Whether you’re working on a small plumbing repair or a large-scale construction project, NPT threads provide the durability and performance you need.

Understanding MIP Threads

In this section, I will explain the key features and applications of MIP (male iron pipe) threads, including their differences from NPT threads and their compatibility with FIP (female iron pipe) fittings. Let’s dive in!

MIP threads are commonly used in various high-pressure piping systems, both in commercial and industrial settings. They are known for their durability and robustness, making them ideal for applications that require reliable connections.

Materials and Construction

MIP fittings are typically made from stainless steel or brass, which ensures their resistance to corrosion and provides strength to withstand high-pressure environments. However, MIP fittings can also be found in other materials such as iron, copper, PVC, and plastic, allowing for versatility in different applications.

Compatibility with FIP Fittings

One crucial point to note is that MIP threads are compatible with FIP (female iron pipe) fittings. The threads on the MIP fitting, which follow the NPT (national pipe tapered) standard, can mate seamlessly with the threads on FIP fittings. This compatibility allows for secure and leak-free connections in plumbing and piping systems.

To give you a visual representation of the MIP threads and their compatibility with FIP fittings, take a look at the table below:

| MIP (NPT Thread) | FIP (NPT Thread) |

|---|---|

| MIP | FIP |

| MIP | FIP |

| MIP | FIP |

I hope this table helps you to visualize the compatibility between MIP (NPT thread) and FIP (NPT thread) fittings. As you can see, they work together seamlessly to create reliable connections.

NPT vs BSP Threads

When it comes to pipe threads, it’s essential to understand the key differences between NPT (National Pipe Tapered) and BSP (British Standard Pipe) threads. While NPT threads are commonly used in North America, BSP threads are popular in Europe and countries like Australia. Let’s take a closer look at how these two types of threads differ.

NPT Threads

NPT threads have a taper angle of 1°47′ and a pitch measured in threads per inch. They feature a 60° angle between flat crests and troughs, providing a reliable seal. NPT threads are widely used in plumbing, hydraulic, and gas transportation applications. They can be made from various materials such as steel, brass, bronze, PVC, and cast iron.

BSP Threads

BSP threads, on the other hand, have rounded crests and troughs with a 55° angle between them. These threads come in two types: BSPP (parallel) and BSPT (tapered). BSP threads are commonly used in Europe and Australia for plumbing applications.

It’s important to note that NPT and BSP threads are not compatible with each other. Therefore, when working with pipe fittings, it’s crucial to ensure you have the correct thread type for your application.

To help you visualize the differences, here is a table comparing the key characteristics of NPT and BSP threads:

| Thread Type | Taper Angle | Angle Between Crests and Troughs | Compatibility with NPT Threads |

|---|---|---|---|

| NPT | 1°47′ | 60° | Not compatible |

| BSP | N/A (rounded) | 55° | Not compatible |

As you can see, while NPT and BSP threads may appear similar, their distinct characteristics make them incompatible with each other. Therefore, it’s crucial to select the appropriate thread type for your specific plumbing needs to ensure a secure and watertight connection.

Understanding Pipe Thread Sizes

When it comes to measuring pipe thread sizes, things can get a little confusing. Unlike standard units of measurement, pipe thread sizes have their unique specifications. Let’s take a closer look at how NPT and BSP threads are sized and measured.

NPT Thread Sizes

NPT (National Pipe Tapered) thread sizes are based on the outer diameter (OD) of the pipe. The size of an NPT thread is determined by the number of threads per inch (TPI). For example, a 1/2″ NPT thread has 14 threads per inch.

BSP Thread Sizes

BSP (British Standard Pipe) thread sizes, on the other hand, are based on the inner diameter (ID) of the pipe. Similar to NPT threads, BSP threads are measured in threads per inch. However, BSP threads have a different taper angle and pitch compared to NPT threads.

To help you visualize the differences between NPT and BSP thread sizes, here’s a comprehensive comparison:

| NPT Thread | Thread Type | Taper Angle | Pitch (Threads per Inch) |

|---|---|---|---|

| 1/8″ | NPT | 1°47′ | 27 |

| 1/4″ | NPT | 1°47′ | 18 |

| 1/2″ | NPT | 1°47′ | 14 |

Note: This is only a small sample of NPT thread sizes. The complete range includes various sizes from 1/16″ to 6″.

| BSP Thread | Thread Type | Taper Angle | Pitch (Threads per Inch) |

|---|---|---|---|

| 1/8″ | BSPP | 1°47′ | 28 |

| 1/4″ | BSPP | 1°47′ | 19 |

| 1/2″ | BSPP | 1°47′ | 14 |

Note: BSP threads are available in both parallel (BSPP) and tapered (BSPT) forms. The above table represents BSPP threads.

As you can see, NPT and BSP threads have distinct differences in terms of thread type, taper angle, and pitch. It’s crucial to understand these variations to ensure the proper fitting compatibility and avoid any plumbing issues.

Choosing the Right Pipe Fittings

When it comes to selecting pipe fittings for your plumbing needs, there are several important factors to consider. From the type of fitting to the thread format and compatibility with other fittings, making the right choice is crucial for a successful installation. Let’s explore the key points to keep in mind when choosing pipe fittings.

Type of Fitting: Male or Female

First and foremost, you need to determine whether you require a fitting with male threads (MIP) or female threads (FIP). Male fittings connect to female fittings, and vice versa. Ensuring the compatibility of the fitting’s gender is essential for a secure and leak-free connection.

Tapered or Straight Threads

The next consideration is whether the threads on the fitting are tapered or straight. Tapered threads, such as NPT (national pipe tapered), allow for a tight seal between fittings and are commonly used in plumbing applications. Straight threads, on the other hand, rely on additional sealing methods such as O-rings or gaskets for a leak-proof connection. Understanding the type of thread you need is fundamental to choosing the right fitting.

Thread Size or Pipe Size

Thread size or pipe size plays a crucial role in selecting the appropriate fitting. NPT and FIP fittings come in various sizes, which are measured in threads per inch. It’s essential to match the thread size of the fitting to the pipe size to ensure a proper fit and connection. Taking accurate measurements and consulting a sizing chart can help you make an informed decision.

Compatibility with Other Fittings

When selecting pipe fittings, it is essential to consider their compatibility with other fittings. FIP fittings should be paired with FIP fittings or MIP fittings with MIP fittings to ensure a secure and durable connection. Mixing different types of threads can result in leaks or improper sealing. Always check for proper compatibility to avoid any issues down the line.

Material Compatibility and Application-specific Requirements

Lastly, consider the material compatibility and the specific requirements of your plumbing application. Different fittings can be made from a variety of materials such as steel, brass, bronze, PVC, or cast iron. Ensure that the fitting material is compatible with the pipes and substances that will flow through them. Additionally, take into account any specific requirements related to temperature, pressure, or chemical resistance.

Taking all these factors into consideration will help you choose the right pipe fittings for your specific needs. It’s important to prioritize compatibility, thread type, size, and material requirements to ensure a successful and durable plumbing installation.

| Fitting Type | Thread Type | Compatibility |

|---|---|---|

| FIP | Tapered (NPT) | FIP (female) to FIP or MIP (male) |

| MIP | Tapered (NPT) | MIP (male) to FIP (female) |

Tips for Assembling Pipe Fittings

When it comes to assembling pipe fittings, there are a few important tips to keep in mind. First and foremost, it is crucial to avoid cross-threading. Take your time and ensure that the threads of the fittings align properly before tightening.

Sealing the threads is another crucial step in the assembly process. To create a proper seal, you can use either Teflon tape or pipe dope. Apply these sealants to the male threads before connecting the fittings. This will help prevent any leaks and ensure a secure connection.

Before using the fittings, make sure to clean the ends thoroughly. Any debris or dirt on the ends can compromise the seal and lead to leaks. A simple wipe with a clean cloth will usually do the job.

Lastly, it is important to avoid over-tightening the fittings. While it may be tempting to tighten them as much as possible, doing so can actually cause the fittings to crack or split. Use a wrench or pliers to tighten the fittings until they are snug, but be cautious not to apply too much force.

If you encounter a situation where the threads of the fittings do not match any other type of fitting, consider using compression fittings. These fittings create a tight seal by compressing a ring or ferrule onto the pipe. They are especially useful when dealing with non-standard threads or when connecting different types of pipes.

By following these tips and techniques, you can ensure a successful and leak-free installation of pipe fittings. Remember to always use the appropriate thread sealant, clean the fittings, and avoid over-tightening. With proper care and attention, you can enjoy a reliable and efficient plumbing system.

Source Links

- https://www.freshwatersystems.com/blogs/blog/how-to-determine-pipe-thread-type-and-pipe

- http://www.differencebetween.net/technology/difference-between-npt-and-mip/

- https://www.wikihow.com/Mip-vs-Npt

- Investing Wisely: How Windows & Doors in Boost Property Value and Financial Health - April 24, 2025

- The Financial Impact of Personal Injuries: Why Legal Help Matters for Business Owners - April 16, 2025

- The Hidden Financial Costs of Domestic Assault: What Business Owners Need to Know - April 16, 2025