Understanding FIP Pipe Meaning in Plumbing

Did you know that choosing the right pipe fittings can make all the difference in your plumbing system? In fact, improper fittings and connections can lead to leaks, inefficiency, and costly repairs. That’s why it’s crucial to understand the meaning of FIP pipe in plumbing and its significance in creating secure and reliable connections.

Key Takeaways:

- Understanding the meaning of FIP in plumbing terminology is essential for selecting the right fittings for your piping system.

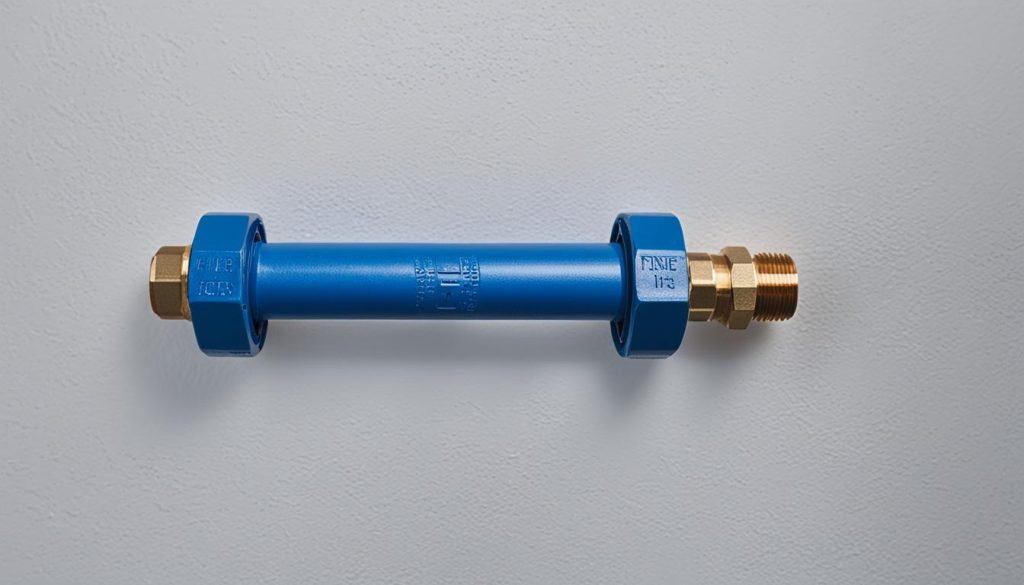

- FIP stands for Female Iron Pipe and is a type of pipe fitting with threads on the inside.

- FIP fittings are commonly made of steel or brass and can be used in various applications, such as gas lines and water hoses.

- Proper installation and maintenance of FIP pipe fittings are crucial for preventing leaks and ensuring a tight seal.

- By familiarizing yourself with FIP pipe meaning and its significance in plumbing, you can ensure a reliable and efficient plumbing system in your home or business.

What Does FIP Mean in Plumbing?

In the world of plumbing, understanding the meaning of plumbing terminology is crucial for anyone working with pipes and fittings. One commonly used term is FIP, which stands for Female Iron Pipe. But what exactly does FIP mean and how does it relate to pipe threads and connections?

FIP fittings are a type of pipe fitting that have threads on the inside, allowing you to connect two pipes or a pipe to a fixture or valve. The threads on FIP fittings are commonly known as Female Pipe Thread (FPT) or National Pipe Thread (NPT). These types of fittings are used to create a secure and tight seal between pipes, ensuring that water and other fluids flow smoothly through the plumbing system.

When it comes to FIP fittings, it’s important to note that they are typically made of durable materials such as steel, brass, or copper. These materials ensure the strength and longevity of the fittings, making them ideal for various plumbing applications.

To ensure a leak-free connection, plumber’s tape or pipe dope should be used when installing FIP fittings. Plumber’s tape is wrapped around the threaded ends of the fitting and helps create a tight seal. Pipe dope, on the other hand, is a type of sealant that is applied to the threads before connecting the fittings. This helps to further prevent leaks and ensure a secure connection.

Understanding the meaning of FIP in plumbing terminology is essential for correctly identifying and using these fittings in your plumbing projects. Whether you’re a professional plumber or a DIY enthusiast, having a good grasp of plumbing terminology, including FIP pipe meaning, pipe thread, and pipe connection will make your plumbing projects more efficient and successful.

The Advantages of FIP Fittings

FIP fittings offer several advantages that make them a popular choice in plumbing systems:

- Durable: FIP fittings are made of sturdy materials like steel, brass, or copper, ensuring their durability and longevity.

- Easy to Install: With their threaded design, FIP fittings can be easily installed without the need for complex tools or equipment.

- Tight Sealing: When properly installed with plumber’s tape or pipe dope, FIP fittings create a tight seal, preventing leaks and ensuring efficient water flow.

Example of FIP Fittings in a Plumbing System

Let’s take a look at an example of how FIP fittings can be used in a plumbing system:

| Fitting | Usage |

|---|---|

| FIP Elbow | Connects a pipe at a 90-degree angle |

| FIP Tee | Diverts the flow of water in different directions |

| FIP Coupling | Joins two pipes together |

| FIP Adapter | Transitions between different pipe sizes or connection types |

As you can see from the example above, FIP fittings are versatile and can be used in various configurations to suit different plumbing needs. Whether you’re connecting pipes, changing direction, or transitioning between sizes, FIP fittings provide a reliable and secure solution.

Now that you have a better understanding of what FIP means in plumbing terminology, you’ll be better equipped to work with these fittings in your plumbing projects. Remember to use the appropriate materials and techniques for installation to ensure a leak-free and efficient plumbing system.

Understanding Pipe Thread Types

When it comes to plumbing, understanding different pipe thread types is crucial for selecting the right fittings and ensuring a secure connection in your plumbing system. In this section, we’ll explore the various pipe thread types commonly used in plumbing and their applications.

NPT (National Pipe Thread)

The NPT thread is the most common type of pipe thread used in North America. It features a tapered design, which allows for a tight and secure connection. NPT threads are typically found on fittings and pipes used for water supply lines, gas lines, and other plumbing applications.

MIP (Male Iron Pipe) and FIP (Female Iron Pipe)

MIP and FIP threads have the same dimensions as NPT threads but differ in their gender. MIP refers to threads on a male fitting or pipe, while FIP refers to threads on a female fitting or pipe. These threads are commonly used to connect different types of plumbing pipes, such as joining metal pipes with plastic ones or vice versa.

BSP (British Standard Pipe)

BSP threads are the standard pipe threads used in Europe. Unlike NPT threads, BSP threads have rounded crests and troughs, offering a smoother connection. If you’re working on plumbing projects in Europe or dealing with imported fittings, it is important to understand BSP threads.

By familiarizing yourself with these pipe thread types, you’ll be better equipped to select the appropriate fittings and ensure a secure and leak-free plumbing system.

| Thread Type | Description | Common Applications |

|---|---|---|

| NPT (National Pipe Thread) | Tapered design for a tight connection | Water supply lines, gas lines, plumbing applications |

| MIP (Male Iron Pipe) | Threads on a male fitting or pipe | Connecting different types of plumbing pipes |

| FIP (Female Iron Pipe) | Threads on a female fitting or pipe | Connecting different types of plumbing pipes |

| BSP (British Standard Pipe) | Rounded crests and troughs for smoother connection | Plumbing projects in Europe, imported fittings |

How to Measure Pipe Thread Size

Measuring pipe thread size is a crucial step in selecting the correct fitting for your plumbing system. Unlike standard units of measurement, pipe thread size is determined by the inner or outer diameter of the threads. To accurately measure pipe thread size, you can use a caliper, measuring tape, or ruler. Here’s a step-by-step guide to help you measure pipe thread size:

- Start by identifying the type of thread: FIP (Female Iron Pipe), NPT (National Pipe Thread), MIP (Male Iron Pipe), or BSP (British Standard Pipe).

- For NPT threads, measure the outer diameter (OD) of the male threads or the inner diameter (ID) of the female threads.

- For BSP threads, measure the distance between the threads in millimeters.

- Use a caliper or ruler to measure the thread diameter accurately. Make sure to measure from crest to crest for tapered threads.

- Refer to a thread chart or consult a plumbing professional to match your measurements to the appropriate pipe thread size.

Understanding how to measure pipe thread size is essential for finding the right fittings and ensuring a proper fit in your plumbing system. With the accurate thread measurements, you can confidently select fittings that will create a secure and leak-free connection.

If you’re unsure about measuring pipe thread size or need assistance, don’t hesitate to consult a plumbing professional for expert guidance.

The Importance of Pipe Connection Types

The type of pipe connection used in plumbing is crucial for ensuring secure connections and preventing leaks. Different types of pipe connections include threaded connections, compression fittings, flare fittings, and barb fittings. Each type of connection has its own advantages and is used in specific applications. Understanding the importance of pipe connection types is essential for selecting the right fittings and ensuring a reliable and leak-free plumbing system.

Types of Pipe Connections

- Threaded connections: These connections involve screwing two pipes together, using threads to create a secure fit. Threaded connections are commonly used in household plumbing for applications such as connecting pipes to water heaters or faucets.

- Compression fittings: Compression fittings use a threaded nut and a compression ring to create a tight seal around the pipe. They are ideal for situations where the connection needs to be easily removable or adjustable, such as with water supply lines to toilets or sinks.

- Flare fittings: Flare fittings are used with pipes that have a flared end. The flared end of the pipe is inserted into the fitting, and a nut is tightened to secure the connection. Flare fittings are commonly used in gas supply lines or with copper pipes.

- Barb fittings: Barb fittings have barbed ends that are inserted into the pipe, and a clamp is used to secure the connection. Barb fittings are often used with flexible hoses or in irrigation systems.

Choosing the right type of pipe connection depends on the specific requirements of your plumbing system. Factors such as the type of pipe material, the application, and the desired level of connection security should be considered. It is important to follow proper installation techniques and ensure a tight, secure connection to prevent leaks and maintain the integrity of your plumbing system.

Benefits of Secure Connections

Having secure pipe connections in your plumbing system offers several benefits:

- Leak prevention: Secure connections minimize the risk of leaks, which can cause water damage and result in costly repairs.

- Efficient water flow: Properly connected pipes ensure smooth water flow, preventing restrictions and improving overall system efficiency.

- Durability: Secure connections are less prone to loosening or coming apart over time, ensuring the longevity of your plumbing system.

- Safety: Well-connected pipes reduce the likelihood of accidents or injuries caused by leaks or bursts in the plumbing system.

Investing in high-quality pipe connections and ensuring secure installations is essential for the longevity and performance of your plumbing system. By understanding the different types of pipe connections and their advantages, you can make informed decisions when selecting fittings and create a reliable and leak-free plumbing system.

Common Pipe Fittings in Plumbing

In the world of plumbing, there is a wide variety of pipe fittings available to meet different needs and requirements. These fittings play a crucial role in joining pipes, changing pipe sizes, and creating connections at various angles. Understanding the different types of pipe fittings and their purposes is essential for properly configuring a plumbing system and ensuring efficient water flow. Let’s explore some of the most common pipe fittings used in the plumbing industry:

Couplings

A coupling is a type of pipe fitting used to connect two pipes of the same size. It provides a secure and leak-resistant connection, ensuring smooth fluid flow between the pipes.

Nipples

Nipples are short sections of pipe with male threads on both ends. They are frequently used to extend a pipe or create connections between two female-threaded fittings.

Couplers

Couplers, also known as connectors, are fittings that enable the connection of two pipes with different diameters. They are a convenient solution for adapting pipes of different sizes within a plumbing system.

Tees

Tees are fittings that have three openings and are shaped like the letter “T.” They allow the connection of two pipes perpendicular to each other while providing a third outlet for another pipe or fixture.

Elbows

Elbows are fittings that change the direction of a plumbing pipe. They come in different angles, such as 45 degrees or 90 degrees, allowing for smooth directional changes in a plumbing system.

Bushings

Bushings are used to connect pipes of different sizes. They have male threads on one end and female threads on the other, allowing for a secure connection between pipes with varying diameters.

It is important to note that when selecting pipe fittings for your plumbing system, material compatibility and the substance that will flow through them should be considered. Using the right pipe fittings ensures a secure and reliable plumbing system that stands the test of time.

| Pipe Fitting | Description |

|---|---|

| Coupling | A fitting used to connect two pipes of the same size. |

| Nipple | A short section of pipe with male threads on both ends, used to extend or connect pipes. |

| Coupler | A fitting used to connect pipes of different diameters. |

| Tee | A fitting in the shape of the letter “T” that allows connection of pipes at right angles. |

| Elbow | A fitting that changes the direction of a plumbing pipe. |

| Bushing | A fitting used to connect pipes of different sizes. |

Tips for Using FIP Pipe Fittings

When it comes to using FIP pipe fittings in your plumbing projects, there are a few important tips that can make a big difference in ensuring a successful installation and secure connections. Here are some key tips to keep in mind:

1. Avoid cross-threading: It’s crucial to take extra care when threading FIP fittings onto pipes. Cross-threading can not only damage the threads but also lead to leaks. Be patient and make sure the threads align properly before tightening.

2. Use Teflon tape: Instead of traditional pipe dope or sealant, consider using Teflon tape during the installation process. Teflon tape is easier to apply and can help create a tight seal, preventing leaks. Plus, it reduces the risk of excess sealant entering your plumbing system.

3. Clean the fittings: Before using FIP fittings, make sure to clean the ends thoroughly. This step is vital to remove any debris or dirt that could interfere with proper thread engagement. Keeping the fittings clean will help ensure a secure and leak-free connection.

4. Don’t overtighten: While it’s important to tighten FIP fittings adequately, be cautious not to overtighten, especially when using plastic fittings. Overtightening can lead to cracks or splits in the fittings, compromising the integrity of your plumbing system. Remember to use your judgment and stop tightening once you feel resistance.

By following these helpful tips, you can confidently use FIP pipe fittings, create secure connections, and achieve successful installations in your plumbing projects.

Source Links

- https://www.certifiedaccessories.com/blogs/news/solving-the-mystery-of-plumbing-abbreviations

- https://www.freshwatersystems.com/blogs/blog/how-to-determine-pipe-thread-type-and-pipe

- https://www.plumbersderby.org.uk/what-does-fip-mean-in-plumbing/

- Investing Wisely: How Windows & Doors in Boost Property Value and Financial Health - April 24, 2025

- The Financial Impact of Personal Injuries: Why Legal Help Matters for Business Owners - April 16, 2025

- The Hidden Financial Costs of Domestic Assault: What Business Owners Need to Know - April 16, 2025